How does underwater welding work? (Explained In-Depth)

Underwater welding is one of the highest-paying welding jobs that is trending in the job market. As a welder, you can become one of them.

Underwater welding needs to be done in a different environment than the normal one. You must have the proper training and knowledge for this profession.

This is undoubtedly an adventurous profession. In addition, your interest in underwater welding may grow as it is becoming one of the most well-paid jobs for welders.

There are a few factors to consider before you decide to become an underwater welder.

Well, don’t worry. We are here with relevant information to enrich your knowledge and interest in underwater welding.

Let’s dive in.

Table of Contents

What is underwater welding?

Underwater welding is a specialized welding process especially done underwater. It is also known to welders as hyperbaric welding.

Underwater welding is the process where welding is needed to be done at elevated pressure.

In addition, this type of welding can be done in water and also in dry conditions.

When done in water it is commonly known as wet welding. On the other hand, if underwater welding is done keeping a pressure enclosure, keeping the welding dry can be defined as dry welding.

How does welding work underwater?

Till now, you have come to know about what underwater welding is.

The question may arise in your mind about how this welding procedure works underwater? Right?

Underwater welding is done in two ways as we have mentioned to you previously.

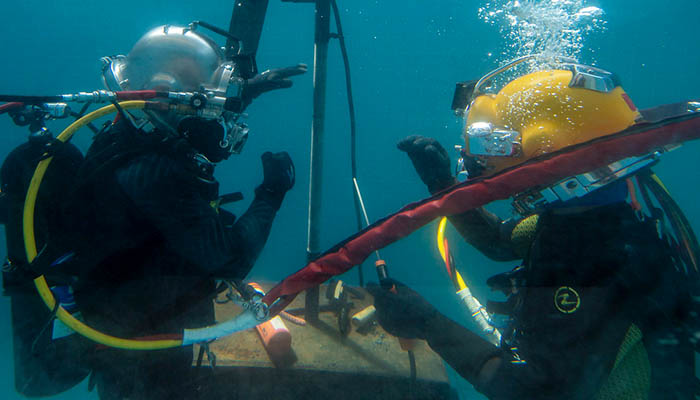

- The wet welding is done using a cable system, the power source is different from the surface welding process. Here the process you need to follow is a bit complicated. You have to use an anode and cathode systems for the process. The process generates huge heat, and the energy produced is enormous. Thus, the welding is done using the waterproof electrode.

- On the contrary, dry welding is done using a hyperbaric chamber. An airtight enclosure needed to be made, these enclosures are of several types generally called “ habitats”. This process is similar to surface welding. The air here continuously fluctuates inside the habitat to keep the environment inside rid of toxic fumes.

Underwater welder training

By now, you must be very enthusiastic about the profession. However, for this, you need to ensure proper training for this risky job.

In the case of the majority, it is seen that a person begins by training to become a professional welder. You have to be good at surface welding first. Followingly, you need to have proper diving training also.

You need to make sure to get yourself educated properly, and trained in a high-quality training institute.

Your training institute will help you to learn and also make you prepare for your diving expectations required in the job.

Besides, further training and certifications will be needed for your desired welding job.

The training you need will be a hard one without any doubt and will take years to complete.

As result, you will be fully prepared to take on the challenges in this job.

Certifications

You need to have proper certifications after your training period.

By earning the topmost welding recognitions, you can ensure your highest return from the job.

Looking forward to becoming an underwater welder, you can earn an underwater welding certification provided by the American Welding Society ( AWS ). This is normally a standard certification for welders.

Your targeted company may test you before hiring as their own standard despite having the needed certificates. So, be prepared for this also.

To sum up, you need to have the proper certification in three areas: Surface welding, commercial diving, and underwater welding to become a professional underwater welder.

How do underwater welders work?

Underwater welders work in water levels especially repairing offshore structures, the pipeline repairing under seawater.

Besides, underwater welding is also needed for submarines as well as nuclear reactors also.

A welder needs to perform in wet underwater conditions and also in dry welding can be done.

Underwater welders can work under a company for a monthly basis payment. They can also take project base work to ensure work freedom.

Welders need to stay in the water diving for a long time and perform the work for long hours in case of wet welding.

On the other hand, dry welding or hyperbaric welding may not expose a welder to water but need to work under high-pressure difference in an airtight chamber.

How does hyperbaric welding work?

Hyperbaric welding is also a dry welding process underwater.

Well, welding inside a hyperbaric chamber needed to be done in a certain manner. The enclosure here is defined as habitats.

Different types of habitats can be used here. The pressure inside is maintained a bit high from the surface level.

The air needed to be pumped into the habitat during welding which is done by the surface team. This airflow helps to get the toxic fumes during welding out of the habitat to ensure a safe environment for welders inside.

As it is a dry welding process, the welding process used here is the same as the surface welding procedures.

Underwater welding: how does it work?

This welding process is different from hyperbaric welding.

Here, you have to weld while completely surrounded by the water with your welding equipment

For this process, you need to have your electrode for your welding, the mechanism here is the cathode anode process.

You need to carry a gaseous cylinder for the flow of electric arc in the welding region through the cathode. The welding area will be considered as the anode.

Due to the particle movement in the welding region, the process is done by generating extreme amounts of energy.

During your welding underwater, the welds will be protected by maintaining gaseous bubbles that form around the arc.

These bubbles can be a mixture of specific gasses including hydrogen, carbon dioxide, carbon monoxide, etc.

Additional bubbles can cause a welder’s vision blurry. It is kind of similar to diving and exhaling underwater. Worry not, you will get used to this problem with time and handle this.

Why is underwater welding dangerous?

Underwater welding may sound interesting but it is surely a risky one for you.

It is due to the danger you may encounter while working underwater.

You will need to operate dangerous equipment underwater that contains risks.

Besides, the injuries can often cause long-term problems to health and even cause death.

The common hazards regarding underwater welding are given below:

- Shock and also explosions are the most common hazard for a welder. You need to wear proper waterproof equipment while welding as a preventive measure.

- Another hazard is decomposition illness. You need to work underwater where severe pressure changes. Also, you need to work under more than 100 feet underwater. These rapid changes are very risky for your health. As a result decomposition illness may occur that needs proper treatment for cure.

- Another hazard is that changes in water pressure can cause the drowning of welders. You have to be very good at diving and coping with the water nature under the sea.

Know Details: Why Is Underwater Welding Dangerous?

Frequently Asked Questions

An underwater welder is always working at the risk of getting electrocuted. To avoid this type of risk you should be careful in selecting a proper suit.

Use rubber gloves and suits under water. The gauntlets of the gloves should be firmly tightened to the wrists to avoid slag floating in.

You should be careful in case of using cables also, strain relief needs to be incorporated in cables.

Besides, you need to apply rubber tape instead of electric tape.

Underwater welding is one of the most paying welding jobs. On average an underwater welder makes about $42,000 yearly in the US. It can vary from $25,000 to $80,000. This may vary regarding your geographical status and experience in the work.

Yes, underwater welding is a great career opportunity for welders who are willing to take challenges of the job. This will ensure some serious money for you.

This actually depends on the type of welding job you are working on. On average it is seen that an underwater welder works underwater for 40-45 hours a week. Accordingly, project base welders may need to stay more than that to finish the project early.

A welder may need to go underwater from 30 feet to even 400 feet deeper for performing a work.

The life expectancy of an underwater welder depends on various factors. Depending on the risk of the job and exposure to different health hazards, it may shorten your lifespan.

Underwater welding is considered one of the most dangerous welding jobs for the risks it provides. In addition, the fatality rate for underwater welding is about 15 percent.

Conclusion

Underwater welding is a specialized welding career for you that is far different from surface welding jobs. You need to acquire proper training and education for the job.

Moreover, it has some demerits and health issues. Keeping the demerits in mind, you can prepare for the jobs. Your consciousness and prevention are a must to ensure a proper welding career.

If you are able to make yourself an underground welder, it is sure that you will have a high return for the job. With proper training, experience, and precautions you can be a high paid successful underwater welder.