Types of Groove Welds: How To Know Which Type You Should Choose?

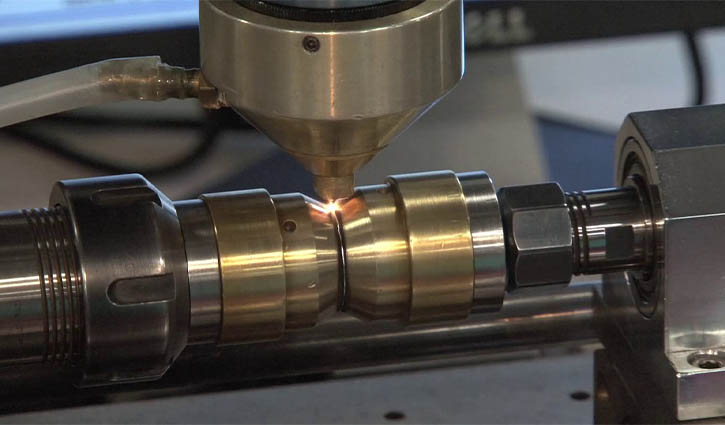

A welding process having void space between two base metals to contain weld beads is referred to as groove welding. This welding process is one of the most used welding techniques. Groove welding is mostly used to join the base metals of the same planes.

Several types of groove welding are frequently used in daily life. In this article, groove welding and its types have been discussed in detail.

To know more and get a clear overview of groove welding, read the full article.

Table of Contents

What are groove welds?

If the welding is performed between two metals of the same plane, then it is known as a groove weld. The welding metals fill the gap and join the base metals with the same strength.

Due to ease of handling and good welding property, groove welding has become one of the most popular welding techniques. Groove welding is mostly used in a butt joint.

Read More: Groove Weld Vs Fillet Weld: What Are The Core Differences

Groove weld types

Groove welding is mainly classified into two based on the welding sides.

- Single groove- If the welding is performed on the single side of the base metals, then it is known as a single groove.

- Double groove- When welding is on both sides of the base metals, it is known as a double groove.

Groove welding can also be classified into several types based on the shape of the groove. Let’s take a look at a few of the most common types

- Square groove

- Single bevel groove

- Double bevel groove

- Single V groove

- Double V groove

- Single U groove

- Double U groove

- Single J groove

- Double J groove

- Flare V groove

- Flare bevel groove

What are the 5 parts of the groove weld?

- Root opening- The deepest penetration part of the weld.

- Reinforcement- It is the excess welding metals from the surface of the groove weld.

- Bevel angle- The angle between a face and a perpendicular axis to the base metal.

- Groove angle- The angle between two faces of the groove.

- Toe- It indicates the edges of the groove welding.

Figure: Parts of groove weld.

What is a groove weld symbol?

Groove welding symbols indicate a brief overview of the types of welding. It is symbolized by following some pre-established standards like AWS, and ISO. It consists of the symbols of groove shape, an arrow pointing to the welding place, and a reference line indicating welding information.

The characters at the left of the reference line indicate the depth of the bevel and the characters right to it indicate weld size. The value of the root opening and groove angle respectively are written at the face of the groove shape symbol.

Figure: Standard symbols of groove welding.

What are grooves used for?

Groove welding is the most common and widely used welding technique. This technique is quite easy and capable of producing stronger welds. groove welding is mainly used to perform butt joints. In other joints like T joint, edge-to-edge joint, corner joint, groove welding may also be used.

These types of joints are often found in various structures and on construction sites.

Read More: MIG Welding Troubleshooting: Common Problems And Solutions

How do you measure a groove?

A groove is formed between the base metals in groove gelding. To measure a groove, first, you have to observe the shape of the groove and measure all the parameters related to the groove.

We need to measure the groove angle and the depth of penetration. The face width and the root opening are also measured. From this information, we can get a clear overview of the groove.

FAQs

In groove welding, the groove angle indicates the angle between the two faces of the groove.

Groove thickness indicates the perpendicular distance between the groove’s top and bottom surfaces.

Although the groove welding technique is applied to perform various joints, it is commonly used in butt joints. Hence, it is widely known as butt weld.

Welding passes indicate the sequence of welding, and how the welding is carried out. There is no fixed number of passes in groove welding. The number of passes depends on the welding position and welding requirements.

Groove weld size is an important parameter of groove welding. It indicates the depth of penetration of the groove welding.

Verdict

Groove welding is a widely used welding technique. This welding technique is mainly used for welding metals placed at the same plane. A groove of different shapes is formed between the base metals and the molten weld bead accumulates in the groove.

Usually, groove welding is classified based on the shape of the groove.