Water Jet Vs Laser Cutting: What Are The Differences?

Material cutting has become an essential process in manufacturing technology. Over the years, a number of methods have been developed for cutting metal. The most popular of them are water jet cutting and laser cutting.

Hence, there are some core differences between these two cutting methods along with some similarities. And having proper knowledge of them will help you choose the most suitable one for you.

In this article, you will find an in-depth guide on a water jet and laser cutting.

Table of Contents

Water Jet

A water jet is an advanced cutting tool, mostly used in the fabrication process to cut metal into a complex shape. It cuts metal using high speed and pressurized (approximately 4000 bar) jet of water containing abrasive. Water jet cutting is suitable for handling a wide range of materials.

Let’s take a look at some pros and cons of Water Jet Cutting.

Pros and Cons of water jet

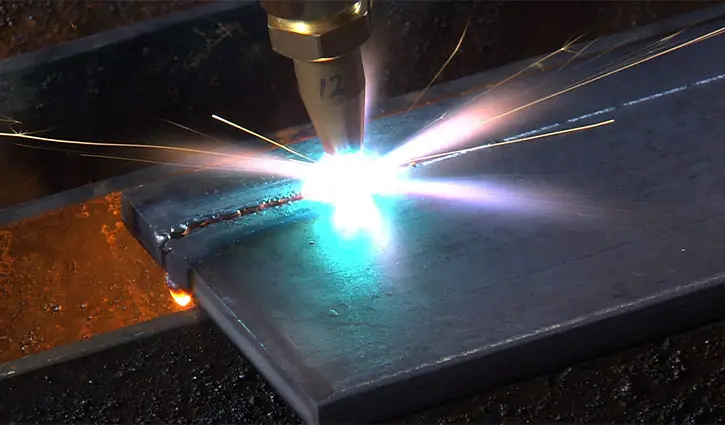

Laser Cutting

Laser cutting is the most common cutting method in the manufacturing industry. It either melts or evaporates material at the laser-pointed area using a focused laser beam resulting in a cut. A high-powered laser (mostly optics) is used in laser cutting. A laser can handle a great number of materials with extreme accuracy.

Let’s take a look at some pros and cons of Laser Cutting.

Pros And Cons of water jet

Similarities between water jet and laser cutting

Material Handling

Both water jet and laser can handle almost all types of materials like rubber, stone, stainless steel, tiles, composite, metal, leather, and so on with a great surface finish. A laser can cut through almost all materials except reflective materials as it reflects the laser emitted on them.

Accuracy and Precision

Both water jet and laser are capable of performing operations with great accuracy and precision. They can maintain great consistency in repeated operations. For manufacturing parts with universal interchangeability, water jet cutting and laser are often used.

Automation

Day by day every, the industry is moving towards automation and most operations are being completed by automatic systems. Water jet and laser cutting technology offer great suitability for the automation process. They support Computer Numerical Control (CNC) systems. Both of their cutting processes are automatic and offer great repeatability with pinpoint accuracy.

Waste

As both water jet and laser have a minimal kerf width (the amount of material cut away while the cutting process), they produce minimum waste.

Differences between water jet and laser cutting

Thickness

- Water jet– As a water jet uses high speed and pressurized flow of water containing abrasive, it can easily penetrate thicker material irrespective of the hardness of the material. It has a range of thickness in cutting operations from 0.001 to 2 inches.

- Laser– As Laser uses amplified light emission to cut material, it has limitations to the thickness of the material. Its cutting process is limited up to 0.4 inches.

Cost

- Water jet– It is more costly than laser cutting. It costs almost $20-$30 per hour.

- Laser– It is less costly than water jet cutting. It costs $13-$20 per hour.

Tolerances

- Water jet– It has tolerances of ± 0.005 inch

- Laser-laser cutting is more accurate than water jet cutting. It has tolerances of ± 0.002 inch.

Speed of Operation

- Water jet– Its cutting speed is relatively slower than a laser. A water jet can cut up to 20 inches per minute depending on the material’s hardness.

- Laser– The cutting speed of the laser is quite faster than a water jet. A laser can cut up to 20 inches/ minute with a better surface finish.

Adverse Effect On Workpiece

- Water jet– It doesn’t have any adverse effect on the workpiece. Water jet performs its operation smoothly.

- Laser– The operating temperature of the laser is extremely high and generates a lot of heat. It adds heat to the workpiece which may affect the internal structure of the workpiece.

Water jet cutting vs laser cutting: Which one should you choose?

The water jet and laser cutting are the two most advanced and highly efficient material cutting methods. Hence, it is a complex decision to choose one completely over another. Each performs better for different materials and different cases. One can be chosen based on our requirements and considerations.

Although laser cutting is limited to a certain thickness, it works more precisely and faster than water jet cutting. A laser can also embed various designs on the workpiece which is not possible with water jet cutting. So for thinner workpieces and embedded designs, the laser cutting process is often chosen over water jet cutting.

Water jet cutting is suitable for almost all types of material and is capable of cutting thicker materials than laser cutting. Also, work hardening is a major concern in laser cutting as it adds heat to the working parts. For these reasons, water jet cutting can be chosen over laser cutting.

Why do we use water jet cutting?

Water jet cutting uses a highly pressured mixture of water and abrasive to cut material which makes it suitable to penetrate thicker materials. As water jet cutting is a cold-cutting process, work hardening can be avoided with this method. So, to process thicker materials where work hardening is a concern, water jet cutting is often used.

FAQs

Laser cutting is cheaper than water jet cutting. Laser cutting costs almost $13-$20 per minute while water jet cutting costs approximately $20-$30 per minute.

Water jet cutting is quite accurate with a tolerance of ± 0.005 inches. But it is less accurate than laser cutting which has a tolerance of ± 0.002 inches.

The price of the water jet machine depends on the size of the machine. However, a small one can be found at $60,000.

Verdict

Water jet cutting and laser cutting are the two most popular cutting methods. Each of them can perform well in different conditions. We can choose anyone based on our requirements.