What Is 6011 Welding Rod Used For? Explained!

The 6011 welding rod is one of the most used welding rods out there. If you are not a professional welder, you might need clarification about which welding rod you should use.

Especially the 6011 as it is widely used, there is a huge chance someone might just recommend you this welding rod. Hence, you should have in-depth knowledge of it.

Now if you want to know all about this welding rod you have come to the right place! Let’s start exploring

Table of Contents

6011 Welding Rod Specification

- The 6011 is known as an all-purpose welding rod.

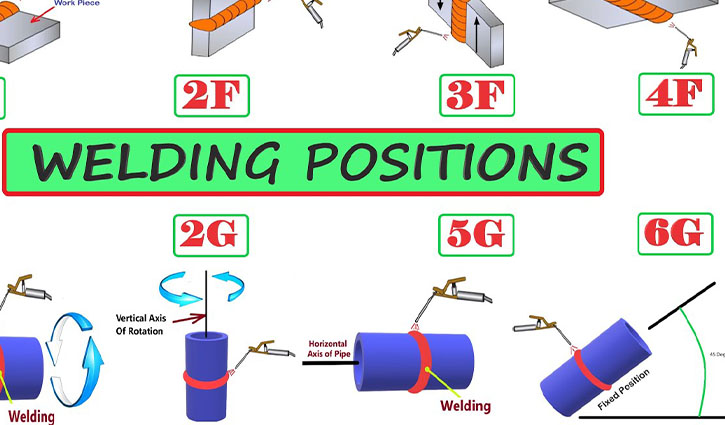

- It can be used in all positions.

- This rod has a minimum 60,000 PSI tensile strength.

- It can be used on AC or DC.

- This electrode can be used on medium to light amounts of painted, dirty, and rusty surfaces.

- The 6011 is used for deep penetration.

- Diameters: 3/32”, 1/8”, 5/32”, 3/16”

- 6011 welding rods are made with an outer layer of high cellulose sodium

Read More: 6011 Vs 6013 Welding Rod: Which One Is Better?

6011 Welding Rod Composition

The 6011 welding rod’s main material is iron. Other materials are also present but have a very low percentage. Other materials are carbon, manganese, phosphorous, silicon, and sulfur.

They range in the 1% range. For its composition, it is not recommended to be stored in humidity above 50%.

Usage of 6011 welding rod

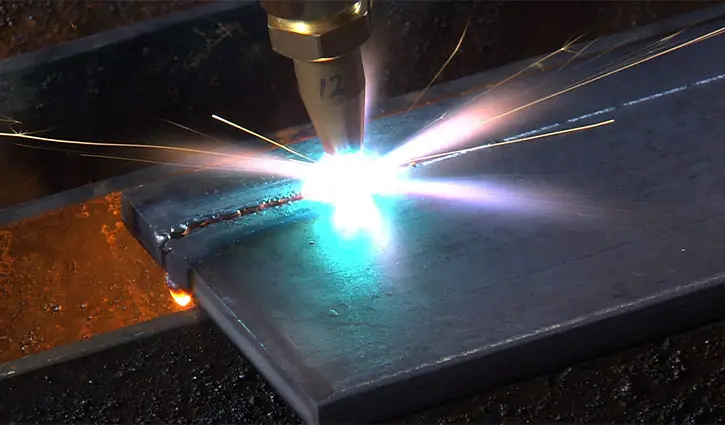

Deep penetration

The 6011 leaves deep penetration. Therefore this rod can be used where a very strong bond is needed. For this reason, automobiles, shipbuilding, pipe welding, storage tank, and other construction use 6011. But for this very reason, 6011 cannot be used with thin sheets of metal because the temperature of welding will literally melt the metal itself.

Iron-based materials

As it is mainly an iron rod, it can be used for most kinds of iron and steel-based materials. Other high-conducting materials like copper, aluminum titanium can also be welded by 6011.

Independent power source

The 6011 can be used both on AC and DC power sources. So, the 6011 is used freely irrespective of the power source type.

Great penetration capability

It is already known that the 6011 is used for deep penetration. This feature makes it a perfect choice for its usability in rusted, painted, and dirty planes or any type of contaminated surface.

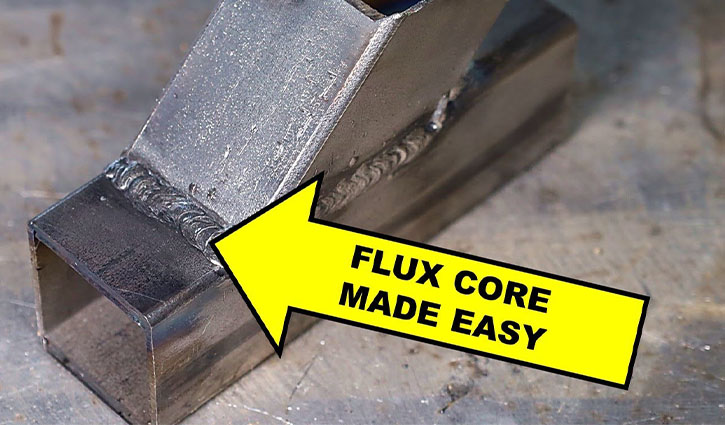

Quick cooling and welding in different positions

Welding by 6011 freezes very quickly as a result welding by 6011 can be done flat, vertically, overhead basically anywhere. Overall the 6011 welds very fast and leaves a very strong bond. So for welding uphill the 6011 is perfect.

Considering all the uses, it is for sure that the 6011 welding rod is a good choice for general-purpose work.

What can you weld with 6011?

The 6011 welding rod is an iron-based rod. So it can be the most iron and stainless steel-based material. Other materials like carbon-based materials won’t work with it.

FAQs

The 6011 is an all-purpose welding rod. It can be used both on AC and DC power sources.

As 6011 freezes fast, it can be used on all positions.

Yes, 6011 is an iron-based welding rod. 6011 is mainly used for iron-based materials.

Yes, you can weld 6011 uphill. This is one of the advantages of the 6011 welding rod. Metal thicker than 1/8″ uphill is a better welding choice.

Welding by a 6011 welding rod is very high. Its welding has a minimum of 60,000 PSI tensile strength. The 6011 is used where deep penetration is needed. So for strong weld 6011 is a good choice.

Yes, stainless steel can be welded with a 6011 welding rod. The 6011 rod is usable with iron-based materials; other materials like aluminum, copper will also work just fine. Although 6011 can be used it is not recommended for best usage. There are special rods only for stainless steel.

Verdict

From the above discussion, I hope your doubt is clear about using the 6011 welding rod. To conclude, the 6011 is an all-purpose welding rod that has great tensile strength and can be used in painted and rusted environments making it a very versatile choice.