Welding aluminum is more complex than welding steel. If you have to weld aluminum plates, you might be worried. No way, there is something that can relieve your worries. A spool gun can make the complicated welding process much easier, more precise, and more efficient. Among the multitudes of options, the 5356 and 4043 spool guns are the most commonly used.

However, you cannot use them as each other’s replacement in each and every case. This can make the welding process more complicated, and in some cases, invalid.

Therefore, having a good idea about them should help you down the line. Let us help you in this regard.

Comparison Table Between 4043 spool gun 5356 spool gun

| Topic | 4043 spool gun | 5356 spool gun |

| Melting Point | Lower melting point | Higher melting point |

| Hardness | Softer | More rigid |

| Weldability | Higher rating | Slightly lower rating |

| Crack Sensitivity | A little lower | More than 4043 spool gun |

What is the 4043 spool gun?

A 4043 spool gun basically acts as a filler alloy. This spool gun has about 4.5 to 6 percent silicon alloyed to the 4000 series aluminum. The added silicon provides an improvement in fluidity, in other words, wetting action.

This causes ease of use for welders, making it a pretty popular choice among them. Moreover, it comes out with almost no debris or soot. Also, the weld has a small frost line around it.

Pros-cons of 4043 spool gun

What is a 5356 spool gun?

A 5356 spool gun consists of aluminum filler alloy with 5% magnesium added to it. The magnesium in the mixture makes it quite hard. Moreover, this facilitates the capacity of anodization.

Pros-cons of 5356 spool gun

4043 spool gun vs 5356 spool gun: Difference

A 5356 spool gun is made by adding 5% magnesium to an aluminum alloy, as we have mentioned before. However, a 4043 spool gun has silicon added to it instead of magnesium in the alloy.

Moreover, a 4043 spool gun cannot weld a 5000 series aluminum. On the contrary, a 5356 spool gun does a great job of welding those.

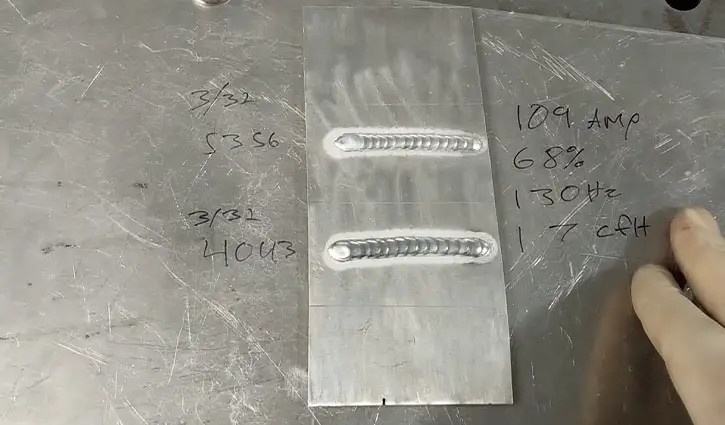

In addition to that, a 5356 creates a considerable amount of smut and splatter, thanks to the presence of magnesium in the alloy. On the other hand, a 4043 spool gun produces a much cleaner weld.

A 4043 spool gun gives a smoother surface than a 5356 spool gun.

The 5356 spool gun has a 26ksi strength in transverse shear. Whereas, the 4043 spool gun can give a 15ksi shear strength when loaded in the transverse direction.

4043 spool gun vs 5356 spool gun: Similarities

You can weld the 6000 series aluminum with the 4043 spool gun as well as the 5356 spool gun. For the 3000 series also, both of the aforementioned spool guns are applicable.

Additionally, Both the 4043 and 5356 produce an equal result on pulse aluminum.

4043 spool guns vs 5356 spool gun: Which One To Choose

According to many, the 4043 and 5356 spool guns are almost identical. So, you may get suggestions to get either one of them.

But, a 4043 spool gun will give you a cleaner and smoother surface along with better looks. Furthermore, you can work in a high-temperature environment using the 4043 spool gun.

In addition to that, These are quite soft and the beads have a shiny look with a smooth finish. But, there are also some caveats. In the case of Gas Metal Arc Welding, findability becomes a serious issue as the 4043 spool gun is softer.

On the other hand, the 5356 is more rigid compared to a 4043 spool gun. So, this gives a better findability in that case. Also, a 5356 spool gun has to be used for welding Marine grade aluminum. Otherwise, the welding will fail. Furthermore, a 5356 matches the colors better after welding.

So we think that, depending on your priority and work environment, the choices will differ as both of these spool guns are good at what they are capable of.

Frequently Asked Questions

A 4043 filler alloy provides a tensile strength of 21000 psi or 145 MPa.

Answer: A 4043 welding rod is used for welding base metals that are heat treatable. For instance, exhaust pipes. Most commonly, it is used to weld 6000 series aluminum.

A 5356 Aluminium can provide up to a tensile strength of 28000 psi generally.

Answer: A 5356 alloy has numerous applications. Among those, the welding of bicycles, boats, ships, pressure vessels, tanks, and automotive parts are the most common usage of this alloy.

Verdict

You will hear from many people that the 4043 and 5356 spool guns essentially have the same usage. However, you should have understood by now that it is not the truth. As mentioned in this article, you must choose either one of them based on your requirements.

Hoping that this article was of help to you, we wish you all the best.