MIG welding and Stick Welding- both are very common welding techniques. MIG welding must be done inside the doors only since it uses an inert gas, which might lead the joint to be affected by wind or rain.

Stick welding, in contrast, can be done outside or even submerged because it is wind and liquid-resistant. This article is solely about MIG vs stick welding.

We will discover the distinctions between stick welding and MIG welding in this article. The benefits of MIG and Stick welding will be covered, along with the best times to use both.

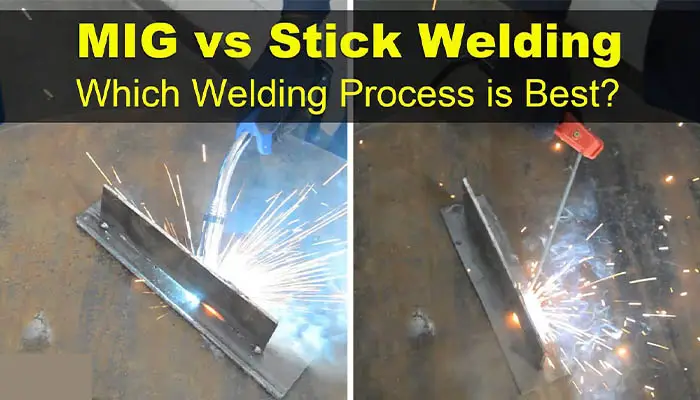

MIG vs Stick Welding

The electrode used to generate the flame and the inert gas are the primary differences between the MIG and Stick welding. Both of them have different uses.

MIG Vs TIG Welding

| MIG Welding | TIG Welding |

| A disposable electrode is used in MIG welding, and it is consistently delivered into the weld area from the cable pool. | The electrode used in tungsten inert gas (TIG) welding is not meant to be eaten. That’s why it remains unchanged and intact at the time of welding. |

| There isn’t a need for more filler. To provide the filler material needed to close the primary space between metals, the electrode body melts. Therefore, electrode serves as filler material. | A thin metal filling rod is fed into the flames to provide more filler material if needed. The filler material is therefore provided separately. |

| According to the weld metals, the electrode metal combination is chosen. The metallurgical makeup of electrode material typically resembles that of the base material. | The material tungsten is frequently used for the electrode, including minor amounts of additional alloying elements. |

| It is appropriate for welding that is homogeneous. Due to the inherent application of filler, autogenous type welding is not possible. | It is especially appropriate for welding in the autogenous method. By adding more filler, it can also be used in a heterogeneous or uniform mode. |

| The filler electrode can just be supplied for a lengthy span of time without replacement due to its extremely long length. | Short length necessitates regular filling change. This mistakenly causes the welding process to stop. |

| The procedure is extremely productive because of the high percentage of filler deposition. | Filler deposition efficiency is so low. It is not entirely productive in this regard. |

| Typically, MIG welding results in a spatter. Due to this, expensive filler material is wasted. | The majority of TIG welding is spatter-free. |

Read More: How To Setting MIG Welding Gas Pressure

MIG Vs Stick Vs TIG

Stick, MIG, and TIG welding are now the three most popular welding techniques. Each method offers a unique set of advantages and drawbacks. Making the right decision will help you avoid a lot of hassle and wasted time.

Unfortunately, there isn’t a welding procedure that works for everyone. There are specific circumstances where the precise, detailed work of TIG is simply required. Other times, a more straightforward technique like MIG or Stick works better since the job’s scope is much too large.

You must fully comprehend each step in order to choose which one will be most helpful to you in any specific circumstance. To assist you in selecting the procedure that is best for you, let’s checkout each of these three steps in detail.

Stick Welding

The earliest, easiest, and most economical of the three techniques covered in this piece is stick welding. As a result, it is one of the most widely used welding techniques and a popular option for novice or hobby welders.

MIG Welding

Mig welding is a reasonably simple process to learn, typically taking only one or two weeks to master the fundamentals.

TIG Welding

TIG welding is frequently regarded as the top level of welding.

Is Stick Welding Harder Than MIG

Stick welding generates spatter and ashes, whereas MIG welds typically have a higher visual quality. On the other hand, in order to avoid affecting the weld penetration while MIG welding heavier metals, the current must be increased and the surface must be entirely clear of paint and contamination.

Stick welding, if done properly, results in stronger connections than MIG welding.

What Is Stick Welding Used For

Stick welding is frequently employed in the building of large steel constructions as well as in the repair and service sectors to join steel and iron together. Stick welding is utilized widely and throughout a wide range of industries, including

- Construction

- Shipbuilding

- Petroleum

- Field Repair

- Structural Welding

- Manufacturing

- Steel Fabrication

- Mining

- Nuclear

- Marine

- Aerospace

MIG Or Stick Welder for Beginner

For a newbie, MIG welding is significantly simpler to understand than stick welding. A lot of factors need to be taken into account when setting up MIG welding equipment, such as the kind and thickness of the wires, the gases, the connection tips, and the injector.

Additionally, MIG welding produces cleaner welds that need less cleaning after the fact. Even though stick welding differs slightly from other arc welding procedures, it is still simple to learn. Therefore, one must begin using MIG welding.

Conclusion

This post was on a comparison of MIG vs Stick welding. Some good visualization has been presented in this article. It also provides a comparison of all three welding methods: MIG, TIG, and stick.

So, this will give the readers a clear idea about these three welding methods.

Read More: Do You Need Gas For Mig Welding?