Can You Weld Carbon Steel To Stainless Steel? Explained!

Completing a welding project using only stainless steel can make it highly expensive. Thus, many welders suggest using this valuable metal only on the core areas and completing the rest using affordable carbon steel by welding with SS.

But can you weld carbon steel to stainless steel? Will it make the bond strong enough and keep the corrosion resistance? Are there any challenges in this welding project?

Read on to learn about all these queries and the know-how process of welding carbon steel to stainless steel.

Table of Contents

Can You Weld Carbon Steel To Stainless Steel?

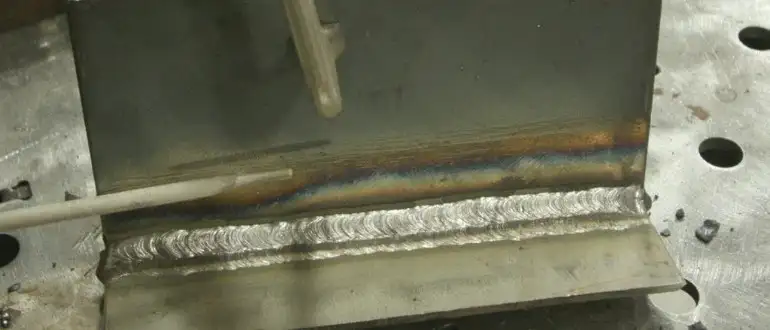

It’s possible to weld stainless steel to carbon steel, but it’s quite challenging. Still, you can have solid results by using the proper filler metal and following the right low-heat process. Otherwise, the project can end up with hot cracking or poor corrosion resistance.

It is better to use your Mig Welder to weld carbon steel to stainless steel (See Best Mig Welder On Amazon Here, If you Don’t Own Mig Welder ).

Is it hard to weld stainless steel to Carbon or mild steel?

A beginner welder is concerned about having good-looking bread on different metals with enough fusion. So how hard is it to weld SS to mild steel?

Welding SS to mild steel is quite tougher than welding pure stainless steel, though they have different properties and compositions. The challenges include, deep penetration, avoiding overwhelm, and focusing on the arc than the stainless part.

To keep the difficulty level lower, the tips you can follow are:

Keep the heat low to prevent deep penetration and avoid carbon contamination. It also helps maintain corrosion resistance. To deliver low welding heat, you should do:

- Set the amperage at the lowest to melt the filler metal.

- Travel at a fast speed.

- Use stringer beads rather than weaving.

- Apply chill bars on or under the metals.

- Create a symmetrical joint that requires the least amount of weld metal.

- Another smart practice is pointing the arc through the stainless part. Even if the angle is rough, batter toe fusion will produce a symmetrical bead.

- If you use a technique that causes slag on the bead, consider a customized angle as it will help avoid slag inclusions.

- It’s also good practice to test on the same scrap metals before starting the main project.

- Another mistake that makes the welding process more difficult is contaminating the stainless part with iron particles. Doing so can cause the stainless part to rust.

- Use a different set of tools to bevel and clean the stainless part. Don’t scratch the SS on carbon steel.

- Don’t preheat the metal, especially when the project is welding austenitic steel. Otherwise, it will lead the project to damage that you wish to avoid. Cool the metal to 150 °C or 300 °F between each bead for multi-pass welds.

How To Weld Stainless Steel To Carbon Or Mild Steel?

Stainless steel is a top choice among DIYers for lots of applications. But for the heavy fabrication, creating a large piece from only SS is quite costly. Thus, some DIYers decide to create the framework and non-vital parts using cheaper carbon steel to reduce the overall cost.

As a result, engineers can only use stainless steel in specific applications. Such as corrosive or high-heat environments. And then they finish the rest using mild steel.

But the fact is, welding steel to stainless steel isn’t quite as straightforward. It requires special attention to the filler materials, details of heat, and joint design to create a strong bond.

For successful operation, its needs the perfect planning, preparation of welding SS and carbon steel, and an expert team of welders and fabricators.

Welding Dissimilar Metals

Following the section, we will reveal how to weld 304L stainless steel and A36 carbon steel. For this, you should have the ability to ½ inch thick stainless steel so you can create more surfaces for the welding. This way, you can create a strong bond between SS and mild steel.

Tools of the Trade

You will need plenty of layouts and measuring tools for this welding project. These are:

- Tape measures

- Squares

- Levels

- Clamps

- Strong lines

You will also have to use an overhead crane frequently to move the workpiece whenever required. To have a strong bond on a heavy plate requires multiple passes of the weld.

Thus, the FCAW welding process is perfect for this project. It’s a semi-automatic welding technique that is quite faster than the GTAW process.

Setting the Temperature

In a part of the project, you have to join the stainless steel and mild steel. Before that, prepare the joint along with preheating, root openings, and max interpass temperature. You have to monitor the heat input stainless closely.

You may need to adjust the heat and keep the time in the sensitization temperature range as short as possible. Remember, excessive heat can reduce the corrosion resistance in the heat-affected area. Hence, careful attention and preparation are crucial for this project.

To weld SS to mild steel, you will need different filler metals. In this case, stainless electrodes with rich alloy content are a good choice.

The reason is that they can prevent admixture of the mild steel into the SS deposit, forming an unacceptable alloy. E309 is a preferable option as this filler metal is commonly used to join stainless steel to mild steel.

Finishing Touches

After welding the fabrication, clean it manually and then send it for blasting. You’ll have to use heavy equipment cranes to move this large shell to the blasting booth. After blasting, paint the exterior finish. Finally, your project is fully assembled and ready for further use.

Reasons to Avoid Welding Stainless Steel to Carbon Steel

Difficulty

Joining two metals, carbon steel and stainless steel adds extra challenges. It costs extra labour, and increases the error rate, and money.

Hot Cracking of the Steel

Stainless steel is more electrically resistant than mild steel. Welding SS using resistance welding generally heats up the metal more quickly than mild steel.

So while waiting for the mild steel to get to weld temperature, SS can become overheated, this can end up with riddling hot fractures. Applying the preheating or filler-based welding method on plain steel can lower the risk. But these aren’t ideal processes for SS metal.

Thermal Expansion in High-Temperature Service Conditions

Another problem of this project is that the heat of the thermal expansion doesn’t affect both metals equally. This variation in expansion rates between stainless steel and carbon metal can produce extra fatigue on the joint. Plus, it can reduce the structural integrity of the wire form and the overall longevity.

Increased Bimetallic Corrosion

Strong corrosion resistance is the key reason that encourages people to use stainless steel. Unfortunately, if you leave the weld of SS and plain uncovered and expose it to harsh corrosive conditions, the joint can cause corrosion.

Reduced Weld Strength

Another downside of joining SS with carbon steel is that it can lead to poor welds even if you follow a filler-based welding process. The operational tolerances and the differences in weld temperatures can sacrifice the welded joint strength.

FAQs About Welding Carbon Steel To Stainless Steel

Stick welding (SMAW) is preferable to welding stainless steel to carbon steel. The reason is that this portable welding rod can produce strong shielding gases. Plus, it’s the most cost-efficient way to join dissimilar metals.

MIG welding is a brilliant method to join stainless steel with mild steel. Even so, it’s the easiest method for novice DIYers and home welders to get a good result with little experience. The MIG welding process is also preferable for welding thin metals.

Final words

Hopefully, you have learned whether you can weld carbon steel to stainless steel. Even the process won’t be so hard if you have experience and apply the right method using the proper tools.

Another key to success is concentration to prevent overwhelm. Filler metal like 309 or 312 will come in handy for solid welding for long-lasting service.