Welding vs Soldering vs Brazing – What’s the Difference?

Anything that requires metal in order to be built needs various processes of metal joining techniques. Among the prominent metal joining procedures, soldering, welding, and brazing are noteworthy.

The metals are found in nature as unshaped and in bits or pieces. Also, they are bendable and reshapeable. This characteristic of metal gave rise to these processes of metal joining to be able to use metal according to our needs.

In today’s article, we will guide you toward these metal joining and reshaping processes, soldering, welding, and brazing. You will get to know how they work, their similarities, and their dissimilarities.

Table of Contents

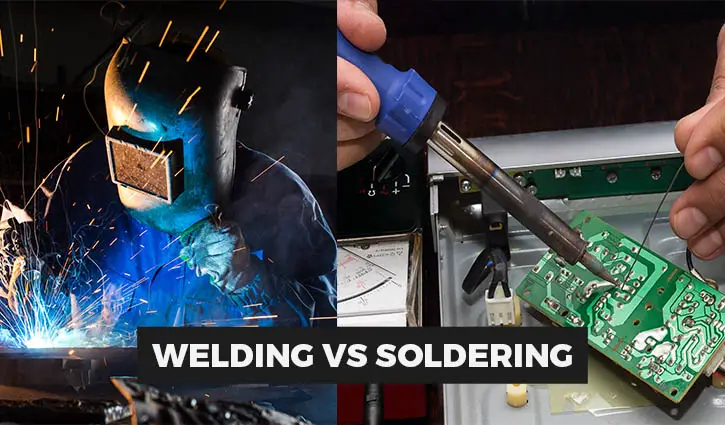

Soldering vs Welding

Soldering and welding are phrases that are frequently employed in the context of sheet metal. Although these two procedures are comparable, their processes and underlying methods differ.

Melting distinguishes soldering from welding most significantly. Metal fabricators don’t melt materials being joined; instead, soldering just heats it. Metal fabricators melt the base metal during welding.

In order to flow the metal into the connection until it cools and solidifies, soldering employs capillary action, which is most comparable to brazing.

Welding:

Metals can’t actually be joined with adhesive—at least not with regular glue. However, you may weld them using the process of fusing them at a high temperature. The fundamental concept is straightforward: use heat to mollify the metals together into a solid junction.

Soldering:

Although soldering and welding appear similar, they are really different. The goal of welding is to create an incredibly strong junction among the metal parts. A welded junction frequently needs to withstand extreme pressures or strain, for instance when joining pieces of a vehicle body.

Usually, the goal of soldering is to create a solid electrical connection. Solder often comes in reels and tubes and it is very soft. In order to link electrical components, solder is utilized in electronic machines.

What is the difference between welding and soldering?

Welding is a technique of uniting components, frequently made of metal, by heating until the contact points melt. On the other hand, the Soldering technique is attaching mostly metallic pieces using a molten substance, with a melting temperature lower than the melting temperature of the base material, in contrast to welding, which is also heat treatment.

Though they are common in many aspects, they have their individual differences in the workplaces

Difference between welding and soldering :

- The most strong joints are those that are welded, soldering comes next, and then brazed ones.

- Approximately 6,500 degrees Fahrenheit are needed for welding whereas 840 degrees are needed for soldering.

- When welding, the metal foundation and the workpieces are melted and heated. The workpieces don’t need to be heated up during soldering.

- ME Mechanical claims that while undergoing a welding process, “Mechanical characteristics of metal may vary at the connection owing to heating the metal and cooling it .” Mechanical characteristics don’t alter at all while soldering.

- Typically, a welder requires more handcrafting mastery than a solderer.

- For a weld, heat treatments are always necessary, while they are never necessary for soldering.

- The workpiece doesn’t need to be heated before welding. However, preheating is necessary when soldering a high-end junction.

Difference between TIG and MIG welding

While performing MIG welding, a MIG torch engulfs shield gas and continuously scorched electrode wire into the region where welding occurs.

When TIG welding, shield gas is given over a usable electrode of tungsten that is held in the flame by a supply field. The electricity is adjusted using a torch-control or a foot pedal while a filler rod is simultaneously manually pumped in the weld region.

TIG welding:

Because the filler material and the flame are different during TIG welding, the welder needs two hands. However, TIG welding may create strong welds without the need for filler materials.

A foot pedal located beneath the TIG welders may also be used to regulate how much power is supplied to the torch. While being done, several arc welding techniques produce spatters. Less spatter and an easy finish are the consequences of TIG welding.

MIG welding:

MIG welding is the process of fusing metal wires that are fastened to electrodes together to form a joint. The wire carries filler materials across the flame and through the molten metal.

Difference between soldering and welding and brazing:

As like one does in soldering, brazing involves the use of a filler that functions as glue more than it functions as a solder-equivalent alloy. To create a trustworthy electrical bridge among the terminals one is putting together, soldering merely involves the melting of an alloy on top of them.

In contrast to welding, the terminals don’t really melt and often they are not altered; the filler just rests on top. However, you operate at a considerably greater temperature (perhaps 450°C or 840°F) during brazing. The filler penetrates the surface of the metals you’re combining, melts, and solidifies to form a strong bond.

FAQs:

The strongest joints are the joints from welding. The next in rank is soldering.

Soldering has several benefits, including the ability to create airtight and liquid-tight junctions, reduced heat energy requirements than brazing or welding, a variety of heating techniques, and simplicity of mend and adjust.