Fiber Laser vs Plasma Cutting: Which Method You Should Go For?

The metal-cutting industry is getting new technologies every day. The two most popular methods of cutting metals nowadays are the fiber laser method and the plasma laser method.

If you are interested to know about these two methods, you have come to the right place.

In this article, we will analyze the two methods by comparing them. They have several factors that are quite unique to themselves. Describing them should give you a broad perspective about themselves. So, let’s start without any further ado.

Table of Contents

Comparison Table Between fiber laser method Plasma laser method

| Topic | fiber laser method | Plasma laser method |

| Accuracy | More accurate with an accuracy of 0.05mm | Less accurate with an accuracy of 0.1mm |

| Energy consumption | More | Less |

| Initial Cost | High | Low |

| Running Cost | Low | High |

| Cutting Speed | High for thin materials | High for thick materials |

What is the fiber laser method?

A fiber laser method entails the use of pump lights from laser diodes. These diodes then send light into a fiber optic cable by emission. The fiber optic cable later amplifies the light and releases it as a laser beam. Using this laser, materials are cut.

Pros-cons of the fiber laser method

With so many advantages, the fiber laser method has some drawbacks too. Having knowledge about these advantages and disadvantages will help you to decide if it’s beneficial for you or your workshop or projects.

What is the Plasma laser method?

When a laser beam is emitted into thin air, it ionizes the air particles. This causes the formation of plasma. This plasma laser is later used to cut materials.

Pros-cons of the Plasma laser method

There are some key benefits and drawbacks of the Plasma Laser method you have to take into consideration for your better understanding.

Fiber laser method vs Plasma laser method- Difference

The fiber and Plasma laser method has some considerable differences. The core difference between fiber laser cutting and plasma cutting are discussed below:

Accuracy:

The plasma laser method can cut metal with an accuracy range of 0.2 to 0.5 mm whereas the Fiber laser with an accuracy of 0.05mm.

Cutting Speed:

The cutting speed for the plasma laser method depends on the thickness of the material to be cut. For thick materials, the Plasma laser method has a higher cutting speed than the Fiber laser method. However, for thin materials, the Fiber laser method has a higher cutting speed than the Plasma Laser method.

Range of thickness of materials:

Thickness is an important factor for both Fiber and Plasma laser methods.

The plasma laser method can cut materials of thickness up to 50 mm with high quality and up to 150mm with average quality. On the other hand, the Fiber laser method can cut materials having a thickness of 25mm.

Type of Materials:

The Fiber laser can cut all types of materials. But the Plasma laser can only cut conductive materials. However, this laser cannot cut non-conductive materials like wood or plastic.

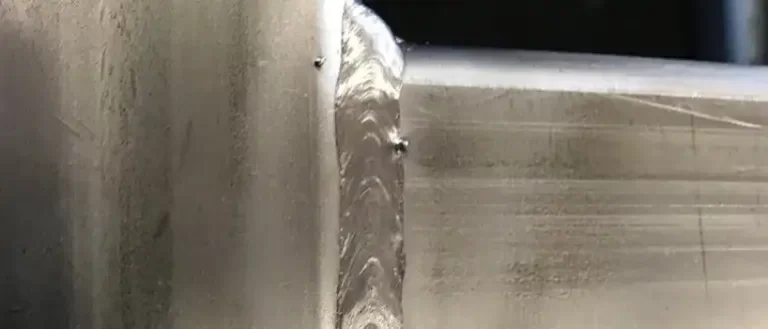

Minimal kerf width:

As the Fiber laser method is more accurate, the cutting gap is tiny, about 0.15-0.5 mm. On the contrary, for the Plasma laser method, it is wider, about 0.5 to 2.2mm.

Heat-affected zone:

The area that is affected by the heat produced from the laser beam during the cutting of materials in the case of the Fiber laser method is small and the reverse is true for the Plasma laser method.

Cost:

Initial or purchasing cost for the Fiber laser method is much higher than that of the Plasma laser method though it varies on so many factors.

But in the case of operational or running costs, both methods are economical compared to the initial cost.

Fiber laser method vs Plasma laser method: Similarities

The plasma laser method has some similarities to the Fiber laser method. For instance, both Plasma and Fiber lasers can cut conductive materials as well as reflective materials with the presence of enough power.

Furthermore, the maintenance cost in both methods is more or less the same.

Fiber laser vs plasma cutting: Which One To Choose

Choosing a method mostly depends on the type and thickness of the material you need to cut for your project or workshop. It also depends on the capital investment.

The plasma laser method offers versatility in lower initial investment. It can cut almost all materials except materials that are not conductive. The precision and accuracy of cutting materials are not as great as the Fiber laser method.

So if your cutting requires more precision and accuracy, the fiber laser method is ideal if you have no problem with the initial purchasing cost.

Frequently Asked Questions

Answer: Laser plasmas are made when high-intensity beams of light produce plasma.

Answer: The Thales and ELI-NP hold the record power level of 10 PW. Right now, this is considered the most powerful laser.

Verdict

This article has covered everything you need to know about the plasma vs fiber laser. If you still can’t decide on which one to choose, consulting professionals might be helpful.

Nowadays, most welding machines have dual voltage support. Hence, you needn’t worry. We wish you the best.