Miller Multimatic 200 vs Lincoln 210 MP (Explained in Details)

Lincoln & Miller are two American welder brands that have rich product lineups. Their multi-process units are almost unmatched in the market.

However, you can’t get a hold of advanced yet budget-conscious ones. That’s where Multimatic 200 and 210 MP can meet your satisfaction.

But they have similar characteristics from the inside. Going through Miller Multimatic 200 vs. Lincoln 210 MP can clear all misunderstandings.

Let’s check out the tabulated comparison between the two versatile products first.

Table of Contents

Comparison Table – Multimatic 200 vs. 210 MP

| Feature | Miller Multimatic 200 | Lincoln 210 MP |

| Weight (lbs) | 29 | 40 |

| Dimensions | 14.5 x 9.75 x 17.0 | 14.0 x 10.75 x 19.0 |

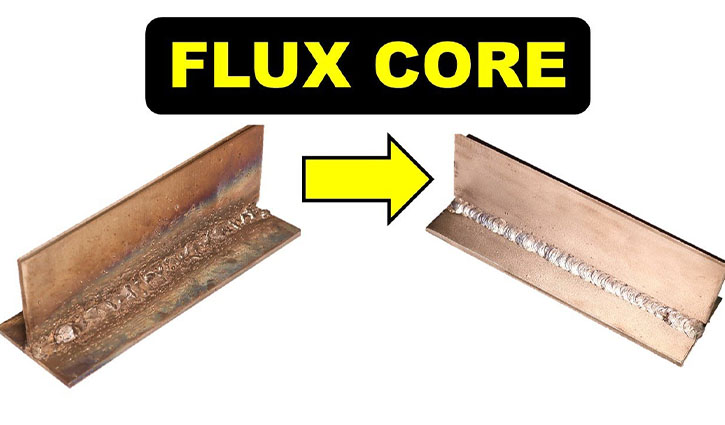

| Welding Process | MIG, Flux-Cored, DC TIG, DC Stick | MIG, Flux-Cored, DC TIG, DC Stick |

| Input Power Rating | 120V or 230V1-Phase, 50Hz/60Hz | 120V or 230V1-Phase, 60Hz |

| Output Range | 5A – 150A (120V)5A – 200A (230V) | 20A – 140A (120V)20A – 220A (230V) |

| Current/Voltage @ Duty Cycle | 100A/14V @ 100% (120V)150A/16V @ 30% (230V) | 100A/19.0V @ 40% (120V)200A/24V @ 25% (230V) |

| Wire Feed Speed(in/min or m/min) | 70 – 425 or 1.8 – 10.8 | 50 – 500 or 1.3 – 12.7 |

| Max Open Circuit Voltage | 90 VDC | 56 VDC |

Miller Multimatic 200 vs. Lincoln 210 MP

However, there are other associated factors to know about each one. You can’t pick a random one based on the comparison only. Looking into their separate overviews can give you a full insight.

Miller Multimatic 200

Miller 200 has many groundbreaking features to enable maximum efficiency. The all-in-1 multi-process welder includes everything necessary in its package. Easy setup in minutes gets you ready for any job.

The inverter tech enables steady arc length and speed without variations. Dual 120V-230V input allows precise MIG, Flux-Cored, DC TIG, and DC Stick. Positive starts with the least spatter ensure stable arcs.

Standard Auto-Set Elite helps with the fine-tuning of the process settings. A multi-voltage plug is set to deliver 120V or 230V input. Its Auto-Line technology provides flexibility to get connected to the power.

A mere 29-lbs device is portable enough for any light tasks. Its impact-resisting case keeps the internal mechanism intact and secure. And the design comes with optional spool guns and a TIG contractor kit.

Pros and Cons of Miller Multimatic 200

Lincoln 210 MP

The multi-process device is a perfect unit to handle small-scale welds. Likewise, the 4-in-1 machine can give you precise MIG, Flux-Core, TIG, and Stick welds. However, its TIG and Stick are limited to DC only.

Many excellent features make it one top-class choice even for pros. Dual input of 120V/230V lets you plug it into the household and commercial outlets. And you’ll get a maximum of 210A output for any task.

Almost everything is present inside the package for its assembly. It features an all-metal wire drive and sheet-metal construction. The protective case is likely to keep damaging elements from causing havoc.

Simple push and turn control enable a fast, effortless, and easy setup. All the advanced options remain accessible for instant adjustments. Even the color display can guide you through the operating process.

Pros and Cons of Lincoln 210 MP

Miller Multimatic 200 vs. Lincoln 210 MP: Similarities

Design:

A sturdy exterior case covers the interior from outdoor elements. The sizes are very similar to one another in terms of dimensions. Guaranteed durability prevails for either machine from top to bottom.

Portability:

Either one is considerably lightweight to allow excellent portability. They have an std handle in the case to enable the carriage. You won’t face any difficulty except for the weight discrepancy.

Power:

Both units support dual voltage – 120V and 230V for common uses. Even the input power rating is the same. However, the single-phase system requires 50Hz for 210 against 200’s 50Hz/60Hz.

Welding:

Likewise, they are 4-in-1 process welders with great precision. You can get DC TIG, DC Stick, MIG, and Flux-Cored outcomes. Also, neither one supports AC TIG for aluminum welding by any means.

Setup:

Assembling the entire machine is simple with either welder. Setup shouldn’t take more than a few minutes to accomplish. But there are certain differences in their actual assembling mechanism.

Package:

Almost everything necessary to weld compatible metals is included. You may still need some additional purchases for specific tasks. But you don’t have to worry about getting things in order.

Miller Multimatic 200 vs. Lincoln 210 MP: Differences

Weight:

200 is noticeably lightweight compared to 210. Miller’s unit weighs about 29-lb against Lincoln’s somewhat higher 40-lb weight. And it can particularly affect your frequent hand carriage to workplaces.

Output:

The output is readily different from one another. The Amp range starts at 5A to deliver a maximum of 200A under 230V. Meanwhile, Lincoln 210 starts from 20A to reach as much as 220A under 230V.

Speed:

Wire feed speed seems compromised in the case of 200. It supports from 70 IPM up to 425 IPM in normal conditions. However, the speed range counts as a more rounded 50 IPM – 500 IPM for 210 MP.

Auto-Set:

Auto-Set Elite is an exclusive feature of Multimatic welders. It allows automated adjustments of setting to produce the best outcome. There’s no such technology available for the Lincoln 210 welder.

Display:

210 manages to outrun 200 in terms of digital display. Lincoln integrated a sufficiently large LCD to let you know the crucial parameters. But the manual settings in Miller lack helpful integration.

Control:

Overall controlling features are simple on either welder. But 210 MP seems to have a digital control to avoid adjustment mistakes. It’ll take a careful change of settings with 200’s manual controls.

Frequently Asked Questions

Miller is somewhat preferable for its superior MIG/TIG welders.

Yes, either machine can weld aluminum to a certain but limited extent.

Lincoln 210 can weld up to 5/16” against Miller 200’s 3/8” thickness.

Wrapping Up

Miller 200 seems to outmatch the Lincoln 210 in different aspects. However, 210 MP makes a stand with its digital, simple, and precise control.

Also, the latter is primarily focused on MIG rather than other processes. So, which one suits your needs satisfactorily is completely up to you.