Welding and Riveting are permanent metal joining operations used for different applications. And of course, there are advantages and drawbacks to both processes. To select the suitable process from these two, you need to know what you want to achieve with the workpiece.

To eliminate the confusion, we are going to go through a comparative discussion on welding Vs riveting in this article.

Selecting the joining process is crucial according to the use of the final product. Aspects such as strength, and aesthetic matter depend on the project.

Let’s get more details-

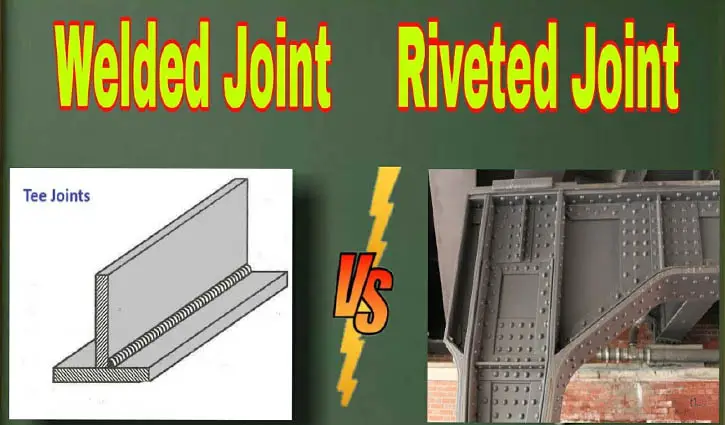

Welding Vs Riveting: a detailed comparison

These two operations are permanent joining processes of metals. This means the joined parts can not be separated without breaking them. These processes are widely used in the industry to create smaller to bigger structures.

Welding

It is a widely used fabrication process of metals. It works on the basis of thermo-softening characteristics of metals. Usually, metals soften when heat is applied and hardens when it rejects the heat and comes to ambient temperature. The change in the molecular density of the metals due to heat comes into play here.

In welding operations, intense heat is applied to the workpiece to melt the joining area. Then a filler material is used to join the workpieces together. For instance, in arc welding, electrodes are used as fillers. The molten filler is known as a weld pool.

Welding has a broader use in almost all industries that require metal fabrication.

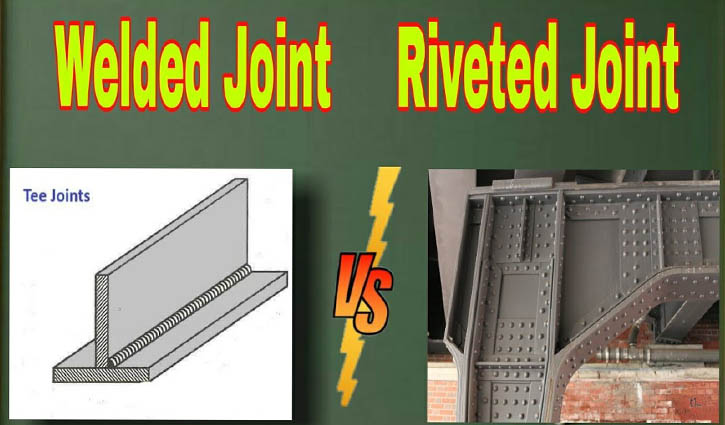

Riveting

Riveting is basically the use of mechanical fasteners to join parts together. The fasteners used here are known as rivets. These are single piece of fasteners that holds together the metal workpieces at both ends.

The work metals must have overlapped holes to pass the rivet through and give a permanent joint. There are several types of riveting operations. Among those, the hot riveting is permanent and the strongest. In another case, cold riveting is done at room temperature which becomes a semi-permanent joint.

The Differences: Welding and Riveting

Although both operations are used for permanent metal fabrication procedures, there are noticeable differences between them. To get the birds-eye view, let us look at the comparison table. It should give you a clear concept of the differences.

| Welding | Riveting |

| 1. Required time for welding is less and the process is straightforward. | 1. Required time for riveting is very high as it involves multiple processes one after another |

| 2. No pre-processing operation of the parent material is required for welding | 3. Parent metal must be processed. Holes are required to overlap the workpieces and make a passage for the rivets |

| 3. Welding can create fluid-tight joints | 3. Cold riveting can not create leak proof joint, hot riveting is a must for fluid-tight structure |

| 4. Welding joints can fail when under intense vibration | 4. Riveting joints are well-performing under vibration |

| 5. Construction with welding is cheap and cost-effective | 5. Riveting is costly as well as time-consuming |

| 6. The welded final piece is lighter, and the weight of the filler is negligible | 6. Output from riveting is heavy as it uses additional fasteners. |

| 7. Load carrying ability remains almost similar after the weld is done | 7. Holes reduce the cross-sectional area, thus the load bearing capacity decreases. |

Read More: Advantages And Disadvantages Of Welding Joints

Welding Vs. Riveting: A Detailed Comparison

Well, now you have at least a somewhat clear idea of the differences. Let’s get into a detailed comparison of the processes.

Strength

Let’s look into riveting vs welding strength.

Welding creates a rigid structure, so the joint becomes strong. The load capacity does not change that much after the work is finished.

On the other hand, the riveting operation is prone to be less strong as the load capacity decreases after process completion. The holes eliminate some portion of the materials, thus it results in less area to distribute loads.

Usage

Welding is popular among manufacturers all around the globe. It also covers a good range of materials. From industrial pipelines to shipbuilding and automobile, from smaller scale to giant structures, welding is used everywhere.

Riveting is most widely used in structural beams. Also used in airplane structures and automotive Chassis.

Pre-processing

You can weld the workpiece straight away. No need to prepare the workpieces before starting the joining procedure. This makes welding an efficient fabrication technique, considering the time and effort.

But the riveting requires pre-processing of the parent material. There need to be drilled holes that will be aligned to passage the metal fasteners for joining. This makes riveting a hectic task.

Appearance

Speaking of appearance, welding will generate a good-looking output. The filler metal fills in the gap in between the joining section. Therefore, after the work is done, the final structure looks more like a single rigid structure. The surface finish stays smooth.

In the riveting technique, the surface finish is not smooth. The fasteners seem like some bumps on the joined area. Those are easily visible and hamper the overall beauty of a structure.

Cost

Welding a structure is cost-effective as it involves a straightforward joining mechanism. It is simple as just placing the metal workpieces and welding them straightaway.

Riveting, an assembly structure is costly as it requires pre-processing and bulk calculations to make a proper connection. This is no single-stage operation. Rather, riveting is a step-by-step procedure.

Frequently Asked Questions

Have you got some queries in your mind? Here are answers to some of the most confusing ones among the readers.

Yes, preferably welding is better when the structure needed to be rigid and strong. Also, welding provides a good appearance than riveting.

Welding is a straightforward process of metal fabrication and confirms the rigidity of the structure. And there is a less visual imperfection on a welded joint.

No, riveting involves multiple procedures, which makes it a time-consuming and costly metal fabrication process.

Final Words

Riveting and welding both work well for permanently joining metal workpieces together. But considering the aspects like the strength of the output, and appearance, welders choose them accordingly. A big structure can also have both the weld and rivet joints in different sections.

This comparison of welding vs riveting should give you the knowledge you require to understand the differences between the methods.