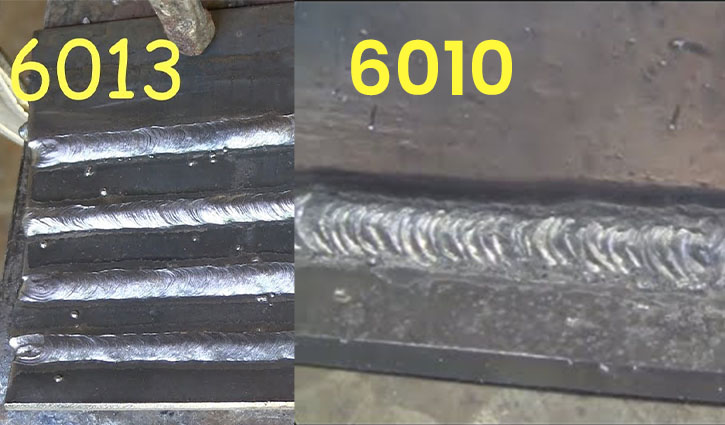

6013 vs 6010 Welding Rods: Which One Will Serve You Better?

For a complicated task like welding, there are many options in the market. Among them, the 6013 and 6010 welding rods are quite popular.

However, they have some distinct qualities that define them. If you have no prior knowledge, the naming of these two rods may confuse you. Moreover, although these two products are popular, they have fundamentally different functions. So, it would be better to know about these products through comparison.

In this article, we will go into further detail about these two products.

Table of Contents

Comparison Table On 6013 or 6010 welding rod

| Topic | 6013 welding rod | 6010 welding rod |

| Coating | High Titania Potassium | High Cellulose Sodium |

| Tensile Strength | 60000 psi | 60000 psi |

| Penetrating Capacity | Shallow | Deep |

| Current | DCEP, DCEN, AC | DCEP |

What is the 6013 welding rod?

The 6013 welding rod is basically an electrode coated with a flux consisting of Titanium dioxide and potassium. It is pretty underpowered. So, it is mainly used to weld thin metal sheets. However, it can be used with both AC and DC power supplies, which can be quite useful in many cases.

Pros-cons of 6013 welding rod

Like everything else, a 6013 welding rod has its fair share of upsides and downsides. We will specify them separately.

Pros

This welding rod creates a seamless inside root, making it a welder-friendly device. Moreover, it produces way less oxidation, thanks to the formation of a clean and bright backside slag. Additionally, it is quite versatile as it can be used with both AC and DC currents.

Cons

Although this welding rod is pretty user-friendly, it is not that powerful. You can only use this rod for welding thin materials. Furthermore, the backside slag is heavy, albeit it is clean and bright.

Read More: 6013 Vs 7018 Welding Rods: Which One Will Be Better For You

What is the 6010 welding rod?

The 6010 welding rod is one of the most commonly used welding rods. This electrode is coated with high cellulose sodium. Moreover, It has a tensile strength of around 60000 psi.

The popularity of this welding rod comes from its ability to penetrate deeply. You can also use it on various surfaces, regardless of their condition.

Pros-cons of 6010 welding rod

The 6010 welding rod is used for a lot of purposes. It has many positives that make it so demanding. However, it also has some negative sides to it. We will discuss them below.

Pros

This welding rod can penetrate deeply, so you can use it to weld most materials. Moreover, the 6010 welding rod is a fast-freezing electrode, which can save tons of time down the line. Furthermore, you can weld on uneven, galvanized, unclean, and painted surfaces using this welding rod. In addition to that, you can easily control the electrode arc. Also, it produces very little slag.

Cons

There are not many considerable downsides to the 6010 welding rod. But, as it can only operate on DC current, it is unable to utilize AC current. Additionally, You will need some experience to use the 6010 welding rod, as it is not so beginner friendly. The backward slag is also tricky to remove. Moreover, You will need to work fast as the welds tend to solidify pretty quickly.

Read More: 6011 Vs 6013 Welding Rod: Which One Is Better?

Similarities between 6010 and 6013 welding rods

First, both the 6010 and 6013 welding rods can be used in all positions to perform welding, making them versatile. Moreover, these two welding rods have the same tensile strength of 60000 psi. Also, both of these welding rods produce a clean arc.

Difference between 6010 and 6013 welding rods

The 6010 welding rod has a high cellulose sodium coating whereas the 6013 welding rod has a high titania potassium coating. Moreover, the 6013 welding rod can utilize both AC and DC currents.

On the other hand, the 6010 welding rod can only operate on a DC current. The slag formed on a 6010 welding rod is flaky, contrary to the easily removable slag on the 6013 welding rod.

Furthermore, the penetration capacity of these two rods is also different. The 6010 welding rod can penetrate deeply while the 6013 rod is only capable of shallow penetration.

6013 or 6010 Welding Rod: Which one should you choose?

Whether you choose a 6010 welding rod or a 6013 welding rod depends on a number of factors. If you choose to weld metal sheets, the best choice would be to use a 6013 welding rod.

On the other hand, if you need to weld stove pipes, or painted or galvanized surfaces, you would be better off using a 6010 welding rod.

Also, if you have to use AC current for welding, you need to choose the 6013 welding rod, as the 6010 electrode is incapable of operating in this situation.

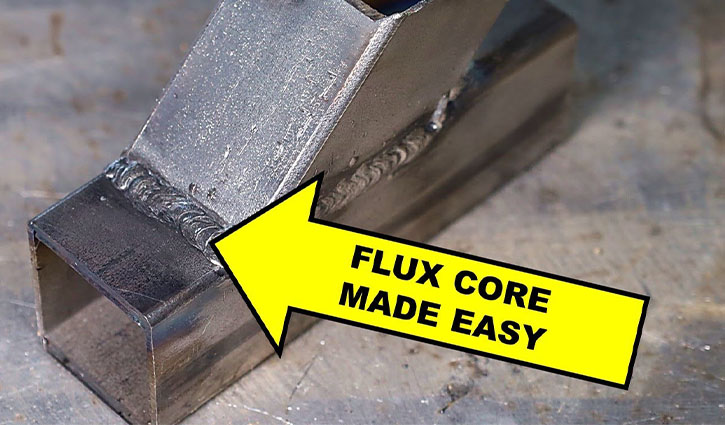

Read More: Can You Weld Aluminum With Flux Core? All You Need To Know!

Frequently Asked Questions

A 6010 welding rod is good for root pass welds. Also, it can be used for welding rusty and unclean surfaces.

A 6013 welding rod can be used in any position. It can work in both straight and reverse polarity.

A 6010 welding rod can operate at its best in between 75 to 125 amperes.

The 6013 welding rod can function between 40-80 amperes, depending on the diameter.

Verdict

As we have discussed in this article, both the 6010 and 6013 welding rods have their distinction from one another. You may choose them according to your need. However, in case you do not have any prior experience in welding, it would be better to hire a professional.

We have tried to cover as much as possible regarding these two welding rods hoping that this article will be helpful to you.