Can Stainless Steel Be Welded To Mild Steel? (Solved)

Well, the question is, can stainless steel be welded to mild steel? The short answer to this question is “Yes,” you can.

There are a few options for doing this. The two metals are joined together by heating the stainless steel to a high temperature and then applying pressure to the joint.

Table of Contents

Can Stainless Steel be Welded to Mild Steel?

You already know that stainless steel can be welded to mild steel. In fact, it is often used in welding applications where the two metals need to be joined together.

The main advantage of stainless-steel welding is that it creates a strong joint that is resistant to corrosion. This makes it ideal for applications where the two metals will be exposed to harsh environments.

There are a few things to keep in mind when welding stainless steel to mild steel.

It is essential to pay attention to the chemical and mechanical properties to avoid possible problems when casting two things. Therefore, it is vital to use an accurate filler metal compatible with both metals.

Besides, following the proper welding method is imperative to limit the heat input for suitable welding. This is because it will reduce the dilution of weld deposits with mild steel parts.

It would help if you considered preventing joint contamination. Avoid warping, cracking, and oxidation for this. This is because it will cause serious welding problems like hot cracking.

Finally, it is essential to use the proper welding techniques to ensure a robust and reliable weld joint.

Read More: MIG Welding Stainless Steel Exhaust – Welding Tips And Tricks

How to stainless Steel be Welded to Mild Steel?

There are a few ways to weld stainless steel to mild steel. Let’s see the whole process of how-to stainless Steel Welded to Mild Steel.

Step 1

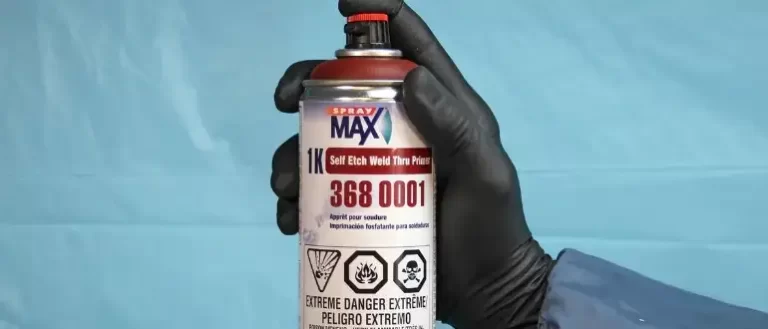

Clean the stainless steel and the mild steel. Remove any rust, paint, or debris from the surfaces of the metals.

Step 2

Set up your welding machine. Make sure the machine is set to the correct amperage and voltage for the electrode and wire you are using.

Step 3

Strike an arc between the electrode and the stainless steel.

Step 4

Begin welding at the edge of the stainless steel. Weld along the edge, moving the electrode in a back-and-forth motion.

Step 5

As you weld, keep the electrode at a 45-degree angle.

Step 6

When you reach the stainless-steel end, stop welding and lift the electrode away from the metal.

Step 7

Let the weld cool for a few minutes before moving on.

Step 8

Inspect the welds for any defects. If necessary, re-weld any areas that are not up to par.

Step 9

Clean the welds with a wire brush to remove any slag or debris.

Step 10

Polish the welds with a stainless-steel polish to give them an excellent finish.

Step 11

Allow the welds to cool completely before using the metals.

That’s it! You’ve now successfully welded stainless steel to mild steel. Keep in mind that welding stainless steel to mild steel can be tricky.

If you’re not comfortable with the process, it’s best to leave it to a professional. Also, be sure to use the correct welding supplies and safety gear to avoid accidents.

What Happens When Weld Stainless Steel to Steel?

When welding stainless steel to steel, the main thing to remember is that stainless steel is more difficult to weld than regular steel. This is because stainless steel has a higher melting point than regular steel.

So, it requires more heat to weld. Additionally, stainless steel is more prone to cracking and warping when welding, so it is important to use the proper welding techniques and materials.

If you are welding stainless steel to regular steel, you will need to use a filler material that is compatible with both metals. Additionally, you will need to use a higher heat setting on your welder.

As well as take care to avoid over-heating the stainless steel, which can cause it to warp or crack. Also, it is vital to use the proper welding techniques to prevent warping or cracking the stainless steel.

At last, if you must weld stainless steel to steel, the best way to do it is to use a stainless-steel electrode and weld in a well-ventilated area.

It is generally best to consult with a professional welder before attempting to weld stainless steel, as they will have the experience and knowledge necessary to ensure a successful weld.

Note That: When welding stainless steel to steel, the main concern is that the steel will contaminate the stainless steel. The best way to avoid this is to use a stainless-steel electrode and weld it in a well-ventilated area.

Frequently Asked Questions (FAQs)

It depends on several factors, including the specific grades of stainless and mild steel being used, the thickness of the materials, the desired strength of the weld, and the welding conditions. Some standard welding rods for welding stainless to mild steel include E308, E309, and E316.

Yes, stainless steel can be welded with a regular rod. The process is similar to ordinary welding steel, but a few things to keep in mind. First, stainless steel has a higher melting point than regular steel, so you will need to use a higher heat setting on your welder.

Second, stainless steel is more prone to warping and distortion when heated, so it is important to use clamps or other supports to keep the pieces in place while welding.

Yes, you can weld stainless steel to stainless steel. The process is similar to welding other metals. keep in mind that you need to use a filler material that is compatible with stainless steel.

Final Thoughts

Hopefully, you have been able to find out how stainless-steel mild steel can be cast. But you have to remember that this is not an easy task at all, so if you are not good at this job, then find a professional. We hope you’ll be able to do this yourself after reading this article.