How to Weld Exhaust Pipe with Flux Core Mig and Tig Welding?

It isn’t unprecedented for your vehicle’s exhaust pipe to require slight fixes after some time. Here, I have briefly discussed how to weld exhaust pipe with flux core.

Table of Contents

The Steps Associated with Welding

To effectively weld a fumes pipe, you should have a few fixed instruments within reach. Obviously, a practical welder is top on the rundown. You will likewise require a hacksaw, processor, and welding cover.

You will find the following four steps when welding your fumes tube.

Cut the pipe:

This cycle isn’t as straightforward as it would show up from the outset. You have to cut the suppressor with extraordinary accuracy as your cutting method will assume an instrumental part in deciding the last debut of the fumes pipe. The initial step is to check out the line and distinguish the cutting territories.

Proceed to utilize a chain pipe shaper to cut the fumes tubing as flawlessly as potentially. Cutting straight will make the activity more expert and appealing. After you are done, you can continue to utilize a processor to eliminate the flaws on the edges and make it better.

Clamp the pieces:

C-clasps will prove to be useful for this.

Spot welding:

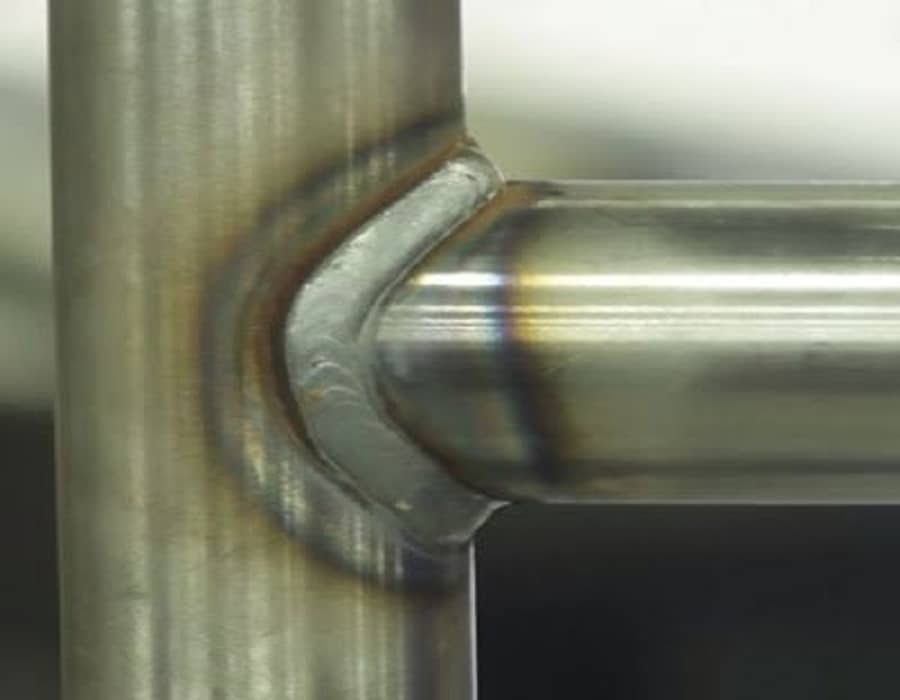

Because of fumes tubing is slender, you should apply spot welds. This is the place you do three or four minuscule welds around the periphery of the tubing. If the holes are made on the contrary side of the cylinder, you can twist them into place.

Complete the weld:

Continue to weld the holes staying in the tubing after spot welding. It is pivotal to weld all-adjust the tubing’s circuit to kill the likelihood of breaks. For a tough and robust weld, I suggest welding over the spot welds.

How to weld exhaust pipe?

I have fixed some flex pipes and fixed a couple of broken fumes frameworks for loved ones. I need to state it is a genuine annoyance, without a doubt.

Before removing the fumes, contingent upon the state of the line, you may need to write down precisely how it was set before nominating it. That is critical to abstain from welding it together in an inappropriate position.

Presently, the fume is quite often grimy, so you have to tidy it up with a wire brush or a processor. Ensure that any harmed or worn-out metal is taken out so you can supplant it with certain portions of sheet metal.

Again, ensure that the closures of the lines are straight, and the joints must be explicit. A necessary stunt to keep the joints consistent and on point is to utilize edge iron while welding.

Moreover, you can connect the point iron under the line with welding braces. It is a little slick stunt that causes you to get everything arranged when you have to weld a straight aspect of the fumes.

How to weld exhaust pipe with the stick?

Some people may say that stick welding isn’t ideal for exhaust pipe fixes. Yet, you will be stunned to discover that you can effectively utilize a stick welder and accomplish extraordinary outcomes.

The 6011 bar is the best for the activity. Pick the most slender 6011 poles you can locate. Utilize a similar spot welding procedure talked about above before welding around the tubing.

However, I realize stick welding isn’t influenced by rust, soil, or paint, yet cleaning is the ideal approach to stay away from slag.

Stick welding is possible anyplace inside and outside. Again, the hardware is modest and straightforward to utilize.

Safety Tips:

- Continuously wear the necessary defensive clothing from gloves to welding covers to keep your skin and eyes secured.

- It is ideal for keeping up a low amperage range to forestall overheating your stick welder and consuming your suppressor.

- Stick welding discharges substantial exhaust; try to weld in an appropriately ventilated room.

- Never weld when the suppressor is connected to the vehicle as the subsequent flashes can prompt blasts.

How to Weld Exhaust Pipe with Flux Core?

While not an energetically prescribed approach to fix your fumes pipe, you can, in any case, utilize gasless motion center welding to DIY fix your suppressor. At the time of welding, it is prudent to clean the tubing to diminish the subsequent splash.

This way, you can lessen the measure of splash flux-core welding produces. Next, you will need to mess with the amperage settings. This type of welding may deliver a sultrier curve to diminish the amperage.

Also, you might need to diminish the wire feed speed. Making shorter dots will guarantee you don’t consume the tubing because of the curve being more smoking.

This method can be possible without a gas-protecting tank and gives better infiltration contrasted with MIG cathodes. Again, the cost is not as much as that of utilizing MIG wires. Additionally, the expense of gear is far less contrasted with MIG and TIG welding.

Safety Tips:

- Wear welding goggles to shield your eyes from the UV beams and the warmth.

- Wear shut-toe shoes to protect your feet from flashes created during the welding.

However, I will suggest learning the MIG and TIG welding exhaust pipe. Again, MIG welding is more qualified for welding exhaust pipes than stick welding.

TIG welding produces less warmth when contrasted with other welding strategies, making it ideal for slim metals. This type of welding is suitable for welding a wide scope of meager metal and amalgams. It is the best way to weld exhaust pipes.

Top flux-core welders for the exhaust pipe:

You have to weld your fumes line and need to set aside cash by doing it without anyone’s help. The least expensive approach to fix a fumes pipe is with a welder. I have inspected various welders based on various measures and made top-notch flux core welders for the fumes pipe. A flux core welder is the simplest welder to set up and is a valuable expansion to any workshop or any DIY specialist working with metal.

Hobart 140 welder:

It is the best flux core welder available in the market. At the point when this welder turns up, it’s easy to assemble. It has all that it needs, and welds astoundingly well for a 140 gasless MIG. The Hobart Handler 140 likewise accompanies a controller and gas line arrangement that you need to do some MIG welding.

The MIG choice of this welder melds practically any metal, including aluminum, which is helpful to have access. The five-year guarantee this welder accompanies is uncommon to discover in other welders, making it more than adequate for specialists and even a decent alternative for light workshop occupations.

Lotos 140 welder:

I discovered the Lotus MIG140 to be an incredible welder for DIY and light workshop use. It runs similarly as pleasant as the Hobart Handler 140.

The shell of the Lotos MIG140 is immense and somewhat flimsier. There is a controller and gas line arrangement you can add to the Lotos if you need to utilize it for MIG welding. The MIG choice likewise melds practically any metal, including aluminum.

However, they are comparative welders and will give you similar outcomes. Again, I will lean toward the Hobart only due to the quality it accompanies.

Exhaust clamps vs. welding

In a perfect structure, an exhaust clamp is only a metal item that is utilized to hold and immovably affix the fumes, and suppressor parts. You fit a fumes clasp around the fumes pipe.

Again, welding is a system of joining two bits of metals with one another to make them a solitary part.

It is a typical conviction that welding exhaust parts together gives the unit a last proficient look. This may be valid, contingent upon your point of view. In any case, welding joints of your fumes framework together make a solid bond that will endure unforgiving conditions. At the point when you capably weld your fumes framework, it will keep it from spilling. Regardless of these advantages, there are drawbacks to welding your exhaust framework.

Welding requires a gifted individual to take at work. An incompetent or unpracticed welder will harm your exhaust framework, making spillage and much more damage to the motor. Therefore, most vehicle proprietors lean toward getting fumes pieces that clasp on your vehicle’s ventilation system.

Second, welding your fumes is testing and requires uncommon hardware to get it through effectively. Generally, welding your vehicle’s exhaust framework should just be finished by an accomplished proficient.

Clamping provides numerous favorable circumstances, particularly to somebody who likes to put in new exhaust segments while in their home carport. The exhaust clamps needn’t bother with fixes, possibly regular fixing when they become free.

Conclusion:

Fumes pipes are not the most effortless pieces of a vehicle to weld. In certain vehicles, the parts are produced using amalgams and hardened steel. In this article, I have provided some exhaust welding tips.

Now you know how to weld exhaust pipe with flux core? However, fumes pipes are generally meager. You must be careful when welding them.

Great article! We are linking to this particularly great post on our website. Keep up the great writing. Lesya Ronald Urita

Thank you

Really informative blog post.Really looking forward to read more. Cool. Alyssa Reisner

Thank you

Great, thanks for sharing this article.Much thanks again. Awesome. Stefanie Arton

Thanks

Thank you ever so for you blog.Really looking forward to read more. Fantastic. Jerold Swecker

Thanks

I am incessantly thought about this, thanks for posting.

Thanks

I reckon something truly special in this website.

Thanks

Some really great info, Gladiola I detected this. I’m not spaming. I’m just saying your website is AWSOME! Thank you so much! Please vist also my website.

Thanks

I must say I read a great article with pleasure

Thanks