Good Weld Vs Bad Weld: Importance of Good Weld

Good and bad things are co-related with each other in this universe. It is also a vital matter in welding and at the time of welding, the welder must have to face many complications. But if he can gain knowledge about good weld then it will be easier for him to differentiate between good weld vs bad weld.

If all the equipment you have used is of better quality then it is quite sure that you will get a good weld With the best qualities product you will get the best weld with your expectation.

Table of Contents

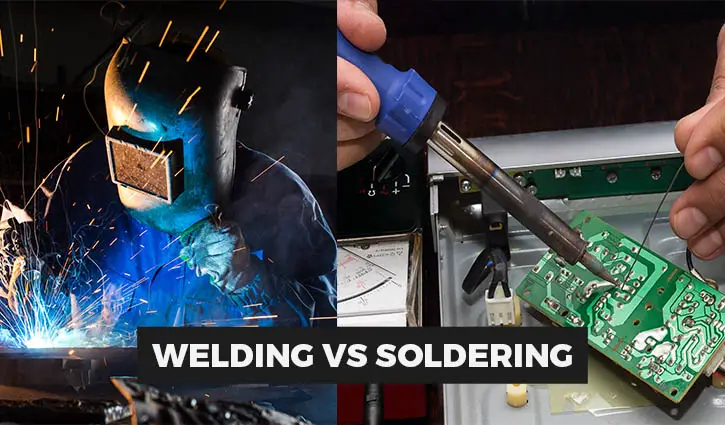

What is welding?

Welding is an industrial process through which two or more metals are joined together by the application of high heat. It is actually a fabrication method that joins metals.

What is a good weld?

To get a good weld the welder must have some special quality with which it will be too much easy to get a good weld.

Actually, a good weld is a weld that is free from any defect and completely different from a bad weld. A good weld must have the following qualities-

- Enough uniformity

- No cracks exist

- The joint must be strong

- Perfect discoloration

Read More: Is Welding Bad For Your Eyes And How To Protect?

Characteristics of good weld

Which weld is really good with its quality and which is

- too much strong

- Which weld has been done with a perfect welding machine then which weld you have got is the good weld?

To get good welds you can buy your welding machine from the brand of Miller, Hobart or Lincoln.

Bad weld and causes

Welding can be bad because of some particular reason and the basic defects of a bad weld is as follows –

- Porosity

- Problematic penetration

- Fusion is incomplete

- Welding crack is available

- Undercut is available

If the process or technique of welding is wrong then you must get a bad weld.

Causes

The main cause of bad weld has created a crack in the weld which is main sign of it. If the welder or the metal or thermoplastic you have used is not of good quality then you will get a bad weld.

Read More: Is Welding Bad For Your Health? Know Details!

5 properties of a good weld:

There are many properties of a good weld but if you search properties of steel then these are as follows –

- Ferritic stainless steels

- Precipitation-hardening stainless steels

- Hard enable stainless steel

- Non-magnetic austenitic stainless steel (303 ss A)

- Stainless steel which is stabilized

These properties are too much important for a good weld.

Examples of bad welds

A weld can be good or bad because the weld is a fabrication process of joining metals or different thermoplastics.

A bad weld has many complications and it is also dissatisfied when you have got a weld that is bad.

For example, Mr. A has started a weld in metal with his welding machine but after completing his weld he found that his weld is not good cause it has-

- A lot of cracks

- If found holes in the bead

- The completed weld is not fulfilled the desired design

- Welding has not been done with the said strength

Here, Mr. A has got a bad weld

How strong the weld is?

Weld is really too much strong than any other metal bond cause it is actually a combination of filler temperament and Foundation temperament. Welding products are stronger than any joining of the metal bond.

What does a good MIG weld look like?

A good MIG weld must have a little palate that is touched by the surrounding metal. If you pulled out the wire it places too much heat in the temperament. MIG weld actually looks like a crown.

MIG welding bead patterns

Learn more about the MIG welding bead patterns techniques which can help you to finish a good weld. Some bead patterns are as follows-

- Small Paw Patrol Perler Bead Patterns

- Zuma paw patrol Perler pattern

- Perler Bead Patterns

- Ezee Beads Paw Patrol Perler Bead Patterns

- Christmas Tree Perler Bead Patterns

- CFree Beaded Jewelry Pattern

- Free Patterns For Bead Weaving

- Free Bead Patterns And Ideas Daisy Chain Necklace Or Bracelet

What causes porosity in MIG welding?

If you found porosity in welding then it is really a bad weld. When you know the difference between a good weld versus bad weld then it will be clear for you when you found any porosity in the weld and then you will understand that it is a bad weld. Porosity is the availability of holes in the weld metal and it released gas.

Welding bead types

There are some types of welding beads and these are –

- Stick Welding Beads

- MIG beads

- TIG welding beads

- Flux Cored MIG Beads

Aluminum welding problems

Aluminum always needs a higher heat for welding, otherwise, you have to face many kinds of difficulties at the time of welding.

- Chemical Composition is not stable

- It can be broken at any time

- Its melting Point is too much low

- Discoloration exist

MIG welding problems and solutions

Every welder has some problems but solution also exists. Maximum time MIG weld faces the problem with the gun liners and contact tips. These are the main cause of creating problems in MIG welding.

Solution

If you found these problems with your MIG welding machine then you can change it or you can contact with the seller of this machine. Miller, Hobart, and Lincoln are the best brand of welders, you can buy them from there then you can minimize your problems.

Read More: How To Clean A MIG Welder Liner? (Tips & Tricks)

What causes pinholes in welding?

When your cylinder’s gas is almost finished then this can make pinholes causing less gas flow and can create in metal.

Weld steel to Aluminum

You can weld steel to aluminum when metals such as Copper, Steel, Magnesium, or Titanium can be welded to it but welding steel to aluminum is a rare case.

Weld aluminum to steel

Steel can be coated with aluminum but you have to place high heat at the time of doing this so that the joining of metals will be very strong as you want.

Final words

Everything has a good side and a bad side and welding are not more exceptional than that thing. The importance of a good weld is beggar description and to get a good weld you must have clear knowledge about good weld vs bad weld.

Only then you can face the complications of welding and can weld easily. MIG welder is one of the best welders in the market but there are some other welders in the market who are really good. By following some instructions you can find the differences in welds and complete a good weld.

Read More: What Size Round Tubing Fits Inside Each Other Easily for Working?