Is Flux Core Welding Strong: How Can You Know It?

Flux core welding is currently a piece of hiped welding machinery that has become very popular among welders, especially beginners. There are a lot of welding types, nevertheless flux core is one of the most wanted welding equipment.

You must be wondering if flux core welding is strong enough to weld thicker metals. If so, then let’s find the answer right now.

Table of Contents

Why is flux core welding considered strong?

The flux core welding is considered strong because of its versatility and strong capability of joining metals without protective gases. Flux core wire welding machines have become popular over MIG welding and another arc welding for their accuracy.

Now, how strong is flux core welding compared to the other weldings? Well, although thick and heavy metal welding methods like MIG (Metal Inert Gas) are much similar to flux core welding, they have different features for different applications. Flux core welding is essential for heavy metallic parts in industrial work to give a strong and secure bond.

Is flux core welding difficult?

Flux core wire welding technology is quite user-friendly and a good choice for beginner welders. Compared to a stick welder, it is a lot easier to just pull a trigger to weld.

For beginners, there are some tips to avoid difficulties such as: Putting the welding machine in the correct polarity, learning to drag the welding gun, cleaning the metal before using it, practicing to pull out the correct speed, and at last being confident!

Flux core welding can produce slag which has to be removed right after welding. Also, it creates spatters and smoke which is a bit hazardous. Despite some of its limitations, flux core welding is capable of excellent performance.

What is flux core welding best for?

Flux core arc welding is very easy to master and widely used in welding dirty or rusted ferrous metals. The process makes the arc smooth and clean at high currents. Flux core welding is an excellent option for outdoor or industrial welding jobs.

You can consider flux core welding when welding thicker metals in all position applications as gas-shield flux core wire has a coating of flux that solidifies quicker than the molten metals. It results in creating a slot to hold onto the molten pool while welding the upper vertically direction.

Is flux core welding any good?

Self-shielded flux core welding is a very useful process for any level of skilled welder. Let’s find out the advantages to know if flux core welding has any good aspects over other welding methods:

All position:

Whether the welding is for home or industrial work, the all-position quality becomes a big deal. All position welding wire has a high demand in the current market. Hence, the flux core wire is one of the most demanding welding methods in the industry.

Dusty metals:

Flux core welding has the unique quality of being able to operate on a rusty and unclear surface with zero obstacles. It is always a good idea to work with a cleaned surface metal. However, if that is not possible, we can weld dusty metals with flux core welding.

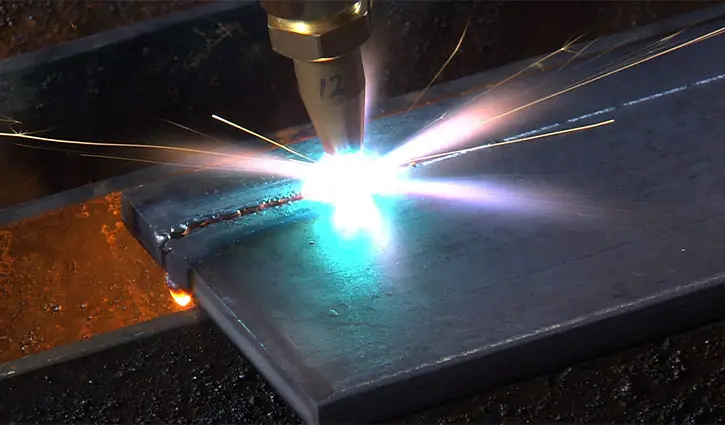

High penetration:

We know that a better penetration level is required in welding thick pieces while pushing the welder. As heat becomes concentrated in electrodes, we get more heat which creates penetration at a low amperage in flux core wire welding. To get the correct penetration we must set the correct diameter of the core wire according to the thickness of the welding material.

Shield gas:

Another beneficial aspect is that the core wire doesn’t require external shield gas as it can produce shield gas by itself. Flux core wire generates shielding gas which protects melted materials from oxygen and nitrogen while stabilizing the arc. Additionally, it collects all slags from the bead before it gets stuck to the cooled metal.

Welding metals:

Flux core welding has a wide range of options in welding metals. The diameter of the core wire varies as the application changes from thicker material to thinner materials. The versatility makes flux core welding more popular especially in industrious works. Besides, we can use it in any small household job.

Frequently asked questions:

Let’s go through some intellectual questions to make sure we haven’t missed any point so far:

A beginner welder should always start with arc welding. Flux core welding is easier than all other arc weldings. Flux core offers a simple trigger-based gun mechanism to weld thick materials.

As flux core wire has the self-shielding quality and does not need any external shielding gas to protect materials, we do not need argon gas to weld with flux core.

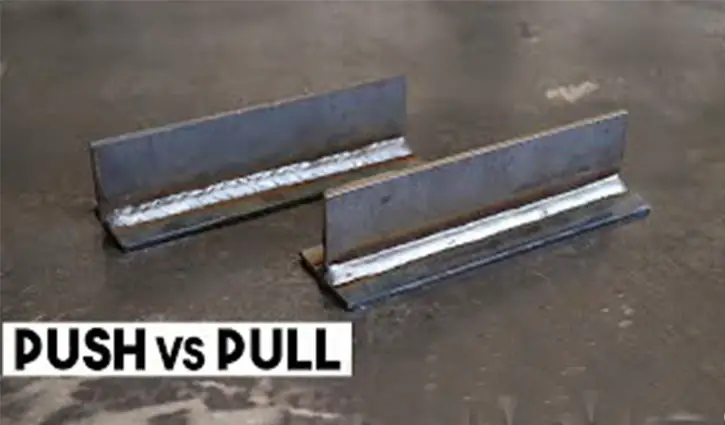

MIG and flux core welding are pretty similar in strength and process.

Both welding methods can provide you with robust weld and metal joints.

A higher penetration level makes a flux core easier to use than a MIG welding machine. Additionally, flux core wire is simpler to grasp than stick-type welding methods.

Verdict

Hopefully, you are no more confused about whether Flux core welding is strong or not. And of course, all the positive sides of this welding prove that flux core welding is strong enough.