Laser Cutting vs. Plasma Cutting: Pros, Cons, Difference and More

Laser cutting and plasma cutting is becoming popular among hobbyists as well as industrial workers. That’s why It is useful to look up laser cutting vs plasma cutting to identify which cutting method is better for your job.

Choosing a suitable cutting method can save you lots of your time and unwanted situations such as deformation or burn-out accidents. So, let’s make an interesting journey on learning about laser cutting vs plasma cutting.

Let us compare Laser Cutting vs Plasma Cutting to get a deep overview.

Table of Contents

Comparison Table On laser cutting vs plasma cutting

| Topic | Laser cutting | Plasma cutting |

| Cutting material | Wood, plastic, rubber, leather, glass, etc | Carbon Steel, stainless steel, copper, aluminum, brass, etc |

| Speed | Fast | Slow |

| Precision | About 0.0005 in | About 0.040 in |

| Metal thickness | Thick sheets | Thin sheets |

| Accuracy | 0.14mm | 0.4mm |

| Cost | High | Comparably low |

| Workspace | Clean | Smoke filled |

Laser cutting:

The laser cutting device generates laser beams that transmit a series of reflectors and concentrates on the metal piece surface, producing heat at the focal to cause a meltdown. Lasers are perfect for carving simple cuts in thin materials which are not reflective.

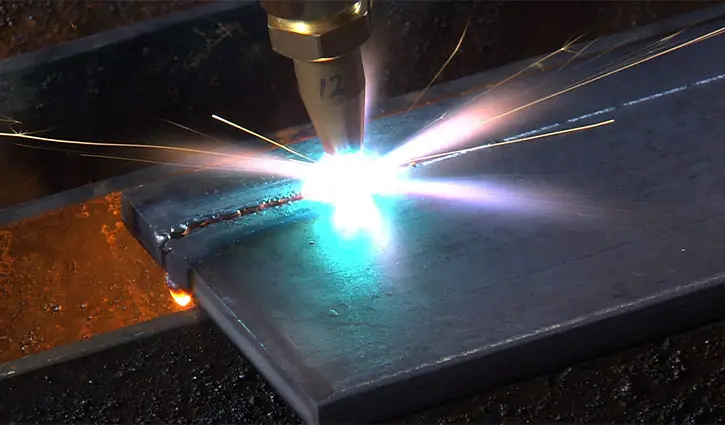

Plasma cutting:

Plasma cutting is a process that creates an electric arc between the anode and cathode. The rush of ionized gas at a temperature of about 20,000 degrees celsius is used in melting and cutting off the material into pieces.

Plasma cutting is generally used to cut off medium-thick sheets. It provides fast speed with slim slots and small deformation at a very low cost.

Read More: Fiber Laser Vs Plasma Cutting: Which Method You Should Go For?

Similarities between laser cutting and plasma cutting

Going through some similarities of both cutting methods might give us a clue about making good use of them.

Technology:

Both laser cutting and plasma cutting use the same technology for cutting the materials into pieces. Laser cutting as well as plasma cutting machines cut off small pieces from materials with the help of computer operating systems.

Deformation:

Although the level of deformation is different for laser and plasma cutting, however, both can create deformation while cutting materials. Plasma cutting creates large deformation when it is used to cut 6mm metal sheets or below. On the other hand, laser cutting produces deformation when cutting thick plates as lasers are more suitable for thin plates.

Hazard:

Laser and plasma cutting has limitations, both of them produce hazardous gas or fumes. Both can create a more or less smoky and noisy environment.

Differences between the two methods can help us feel doubtless. Let’s take a look:

Difference between plasma vs laser cutting

Differences between plasma and laser cutting will help us decide which one is useful for our particular job.

Structure:

A laser cutting machine uses a laser that concentrates a bunch of light photons and uses it to cut through the material. The high-powered light beam heats and melts the metal or any material that it comes into contact with.

Nevertheless, plasma-cutting machinery produces a highly concentrated channel of conductive gas that transmits the energy from a power source to the cutting material.

Cost:

Laser cutting becomes cost-effective when it’s used in cutting thin plates. In addition to that, later maintenance demands a lot of costs. On the other hand, plasma cutting is comparably low in cost, however, it increases labor costs for creating cutting slags and deformations.

Usage:

Lasers can’t cut reflective materials like copper materials. It only cuts thinner plates. Plasma can cut through any conductive metal, however, it resists surfaces like plastic, wood, glass, and some other materials.

Plasma-cutting technology cuts through thicker plates of metal. In general, a plasma cutter uses electrically conductive gases to create the indent, instead of a light beam.

Which flux core should you choose between plasma and laser cutting?

If you are required to cut thin non-reflective metals and you have a short time but a high budget, you should choose the laser cutting method. You can also check out CNC laser vs plasma cutting as a CNC laser cutter which is a piece of ‘computer numerical control’ used to form custom metal shapes.

On the other hand, if you are looking for a method to cut thick plates with reflective quality, you can use plasma cutting in a low-cost facility. Additionally, You can check out high-definition plasma vs laser as high-definition plasma introduces HD plasma, CNC, and high-density plasma which are the latest technology in plasma cutting.

Frequently asked questions:

If you still have questions regarding laser cutting vs plasma cutting, here’s a quick solution for you. You can gather more useful information from the questions below:

If you are on a 150W laser and cutting ⅛ inch acrylic plastic, it will cut 3-4 inches per second. In the case of a plasma cutter, it speeds up to 20,000 feet per second at a temperature of about 30,000 degrees Fahrenheit.

Plasma cutting requires gas to work and create plasma. The most general gases used are nitrogen, oxygen, and argon. Besides, a variety of gases are used based on the application.

Laser cutters can cut a variety of metals from mild steel to stainless including non-ferrous metals. It can cut reflective metals with the thickness of the metal being anywhere up to 30 mm.

Lasers can’t cut reflective materials like copper materials. It only cuts thinner plates. However, lasers can cut through surfaces like wood, plastic, glass, and other materials.

Read More: Difference Between Mild Steel Vs Stainless Steel

Verdict:

After gaining knowledge about laser cutting vs plasma cutting, you can conclude that both types of cutting technologies are beneficial for you based on the application. Also, you can easily be rational about your requirements by considering Laser Cutting vs. Plasma Cutting.