What Is The Welding Rod Made Of – Composition And Specification

The welding rod is mainly made of steel along with some other coating. And a welding rod is used to join two metals using a third metal. However, you can find different types of welding rods in the market. They differ in their working principle and build materials.

If you are planning to get started with welding but have no sufficient knowledge, things might get tricky for you.

Hence, in this article, we will explain the constituents of a welding rod.

Table of Contents

What type of metal is a welding rod?

Welding rods consist of different types of metals, mostly based on their models and criteria for usage. Here is a list of the most used metals that create a welding rod:

- Mild steel

- Stainless Steel

- Cast iron

- Different alloys

- High carbon steel

What is the welding rod made of?

As mentioned before, the main component of a welding rod is mainly steel. However, welding rods also consist of various types of coating and sometimes, aluminum or bronze alloys are used. Moreover, various elements are used in different amounts in a welding rod.

Read More: What Is The 6010 Welding Rod Used For? Explained!

What are welding rods coated with?

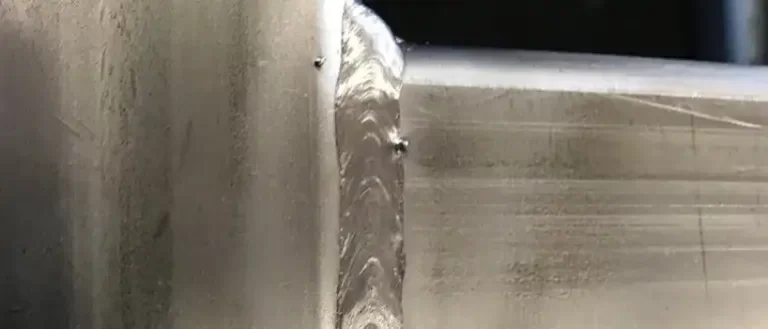

Welding rods are coated with different materials having various compositions. This creates a clean and strong weld along with a more stable arc when compared to a welding rod without coating.

The most commonly used coatings are low hydrogen, iron powder, high sodium, and high cellulose coating. In simpler terms, a welding rod is coated with organic materials, a mixture of various minerals, iron powder, silicates( mainly potassium or sodium), and ferroalloys.

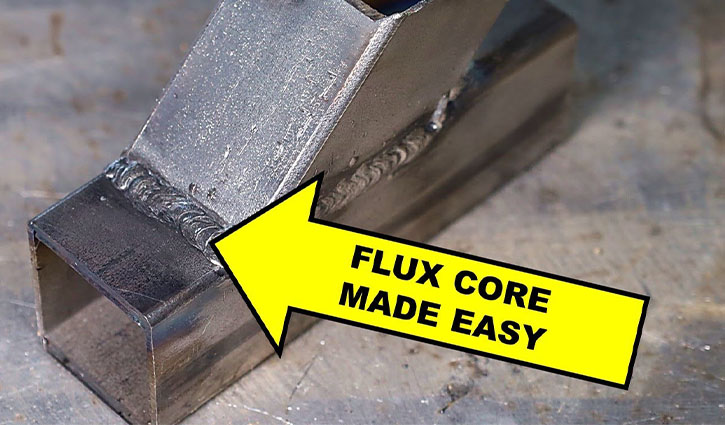

In the case of flux coating, however, the welding rod is coated with a layer of chemicals. This prevents the welding rod from various atmospheric contaminants and also helps with the removal of impurities.

Read More: 6013 Vs 6010 Welding Rods: Which One Will Serve You Better?

How are stick welding rods made?

Making a steel welding rod is an industrial process.

- First, numerous metal wires are created as the welding core. As mentioned previously, the metals used are mostly iron and steel.

- After that, the wires are passed through a machine to make them straight. Then, the electrodes are cut into varying lengths depending on their usage.

- Following that, the materials for coating the wire are created.

- To do that, elements like sodium, aluminum, carbon and manganese are mixed together in a machine with some glue until they get the consistency of wet sand.

- Then, they are turned into giant hollow cylinder blocks.

- After that, 4 of those blocks are placed together in a machine.

- Later on, the electrodes are passed through that machine.

- Finally, a coated welding rod is formed. In this process, about a thousand electrodes are created in a minute.

However, this is not the end. After coating the electrodes, the coating at the end of the electrodes is cleaned off. This gives an overall better grip to the welding rods as well as makes the conductivity much better.

Lastly, the electrodes are coated in various colors depending on their model.

What causes welding rods to stick?

The main reason for a welding rod to stick is current. If you do the welding job with a low ampere, the welding rod will not melt. Rather, it tends to stick to the metal surface. To prevent this problem, it would be best to run the welding rod at the optimum ampere.

Moreover, if you do not keep the welding rod moving, it will get stuck. It is pretty annoying to remove the welding rod once it gets stuck. Hence, keep the welding rod moving while welding.

Frequently Asked Questions

Yes, many welding rods have lead in them. Along with various minerals, lead is also used as a coating for the metal core. It may pose a severe problem if anyone breathes in the fumes during welding.

There are various reports regarding this. Many welders seemed to have lower sperm count, decrease in fertility, and change in hormone levels after being exposed to the welding fume for long hours.

To put it bluntly, yes. If you are exposed to weld fumes for a long time, your vocal cord, lungs, and urinary tract might get affected. So, it would be best to weld in an open space while taking proper safety measures.

According to most people, the 6013 welding rod is the easiest to use. It can be used in all positions and the arc is clean. Moreover, the slag is easily removable. Additionally, it runs at a lower temperature than other electrodes. It is also capable of operating in both AC and DC currents.

Verdict

In this article, we have mentioned almost everything possible regarding welding rods. We hope that reading this article has given you a greater idea about the constituents of a welding rod.

As mentioned in the article, without proper management, welding may cause harm to your health. So, if you are not sure, it would be better for you to hire a professional.

It would be a matter of happiness for us if this article was of help to you. We wish you all the best.