Miller Big Blue 400 vs Miller Big Blue Pipe Pro (Explained)

Heavy welding applications require a powerful welder-generator combo. And Miller’s Big Blue is sure to meet the satisfaction.

Miller’s Big Blue 400 and its updated Pipe Pro are famous for steady power. But you need to invest in the right one as they share too many similarities.

That’s where Miller Big Blue 400 vs. Pipe Pro makes more sense. We managed to have all the answers you need for the purchase.

Dive into the detailed comparison between the two heavy-duty welders.

Table of Contents

Comparison Table – Big Blue vs. Pipe Pro

| Feature | Miller Big Blue 400 | Miller 400 Pipe Pro |

| Weight (lbs) | 993 | 993 |

| Dimensions (inches) | 32.0 x 26.25 x 56.0 | 32.0 x 26.25 x 56.0 |

| Generator Input | 1-Phase, 84A/42A,120V/240V, 60Hz | 1-Phase, 84A/42A,120V/240V, 60Hz |

| Power Output | 12,000W (Peak)10,000W (Continuous) | 12,000W (Peak)10,000W (Continuous) |

| Welding Current | 20A – 400A (TIG)20A – 400A (Stick)14V – 40V (MIG) | 20A – 400A (TIG)20A – 400A (Stick)14V – 40V (MIG) |

| Welding Process | MIG, Flux-Cored, DC Stick, DC TIG | MIG, Flux-Cored, DC Stick, DC TIG |

| Engine Horsepower | 24.7 HP @ 1500rpm (Idle) / 1800rpm (Weld) | 24.7 HP @ 1500rpm (Idle) / 1800rpm (Weld) |

| Weld Output at100% Duty Cycle | 300A at 32V350A at 27V400A at 24V | 300A at 32V350A at 27V400A at 24V |

| Max Open Circuit Voltage | 85V/30V | 85V/30V |

| Noise Level | 68.7dB (Idle)72.1dB (Weld) | 65.0dB (Idle)71.2dB (Weld) |

| Capacity | 11.5-gal/43.5L (Fuel)6-Qts/5.7L (Oil)6-Qts/5.7L (Coolant) | 11.5-gal/43.5L (Fuel)5.8-Qts/5.5L (Oil)10-Qts/9.5L (Coolant) |

Big Blue 400 vs. 400 Pipe Pro

Almost all the technical parts seem to have similarities to one another. Also, you shouldn’t decide based on the comparison only. Looking into the devices individually can help you catch their efficiency closely.

Miller Big Blue 400

Big Blue gets designed with professional uses in mind. The welder-generator combo is sure to give superior workplace productivity. Its diesel engine-driven system constantly performs in any condition.

The multi-process device is excellent for std MIG, Stick, TIG, and Flux-Cored welding. But you can only get DC Stick/TIG with its mechanism. Also, you can utilize the powerful air carbon arc to great extents.

Built-in USB lets you install and upgrade the latest software versions. It can help you with diagnostics and statistics. Meantime, its ArcReach tech enables you to control the arc parameters from a distance.

4 different engines are available to fit into the system. You can get – Mitsubishi, Kubota, Caterpillar 1.5 or 1.5T. And the change relates to additional weight, HP, and noise level alongside the fuel, oil, coolant capacity.

Pros and Cons

Miller 400 Pipe Pro

Take your Big Blue experience to the next level with the Pipe Pro. It’s perfectly suitable for heavier industrial applications. However, its process is particularly special for transmission pipeline welding.

Likewise, the welder generator can have two different variations – Mitsubishi or Caterpillar. It only distorts the capacity and weight. Everything else remains the same for available welding processes.

Pipe Pro is the smallest, lightest, and most powerful one in its class. A top-notch enclosure protects the assembly from outside elements. Dynamic DIG enables superb arc flexibility with penetration control.

There are a wireless control panel, ArcReach tech, and USB connection port. It delivers precise MIG, DC TIG + Stick, and Flux-Cored processes on demand. You can establish total control of the welding action.

Pros and Cons

Miller Big Blue 400 vs. Pipe Pro: Similarities

ArcReach:

No need to use a control cord set the welding parameters. Big Blue features ArcReach tech to enable simple controls. You can save a trip to the power supply to change the settings or parameters.

Input:

Voltage and current rating remain the same for either of the devices. Standard 120V/240V input should make the generator function.

Process:

You can perform MIG, Flux-Cored, DC Stick, and DC TIG welding. And it’s true for both welders. They even have similar amperage and voltage ratings. Their uses are different despite the same rating.

Output:

Even the output shares no notable differences between the two. No changes exist, whether it’s the generator or welder.

Control:

Wireless control interface is present in either of the Big Blue products. Its hassle-free control lets you do almost everything in seconds. This feature itself contains many helpful systems for the user.

Update:

Miller enables automated mechanical logs for the welders. An extra USB port even updates the essential programs.

Miller Big Blue 400 vs. Pipe Pro: Differences

Engine Type:

Big Blue 400 can hold 4 different engine types. But 400 Pipe Pro can vary by two engines only. You’re to check for Mitsubishi, Caterpillar 1.5/1.5T, and even Kubota for the alternatives.

Oil Capacity:

Oil capacity is somewhat higher in Big Blue 400. So, you can enjoy a slightly longer welder runtime.

Application:

400 Pipe Pro is exclusively for heavy uses like pipeline welding. But Big Blue 400 is good for normal-level heavy welding. It includes – fabrication, repair, maintenance, and construction.

Noise Level:

Noise is slightly higher in Pipe Pro. However, their levels are different from the Mitsubishi engine.

Carbon Arc:

Air carbon arc is more powerful in Pipe Pro. Its 6.4mm or ¼” nominal can deliver more on further loading. But the arc in Big Blue 400 can deliver as much as 6.4mm with a 4.8mm rating.

Frequently Asked Questions

Massive weight of Big Blue welders aren’t very portable.

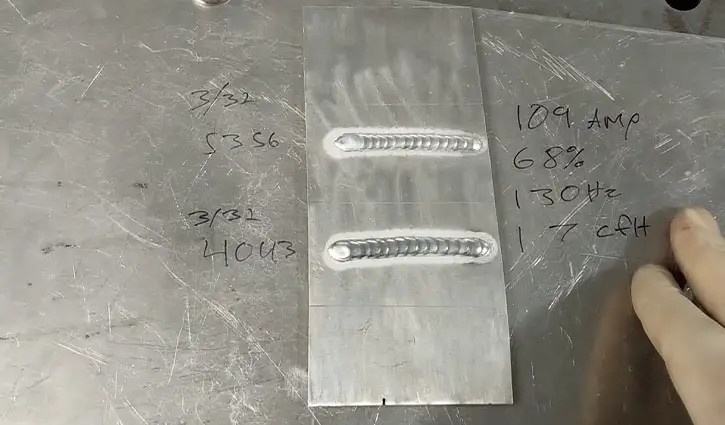

Yes, you can weld Al with Big Blue through a proper setup.

It reduces the OCV to 30V, increasing the operator’s safety.

Wrapping Up

Big Blue 400 is suitable for common applications with sufficient power. And Pipe Pro is perfect for heavier pipeline welding uses.

So, it’s in your best interest to choose the more applicable one for the price.

But Big Blue 400 may not handle large-scale pipe welding well enough. That’s where you’re to buy Pipe Pro for satisfactory outcomes.

Read More: The Miller Bobcat 225 Welder Problems: Top 5 Issues With Solution