Can You Weld Through Self Etching Primer? Explained!

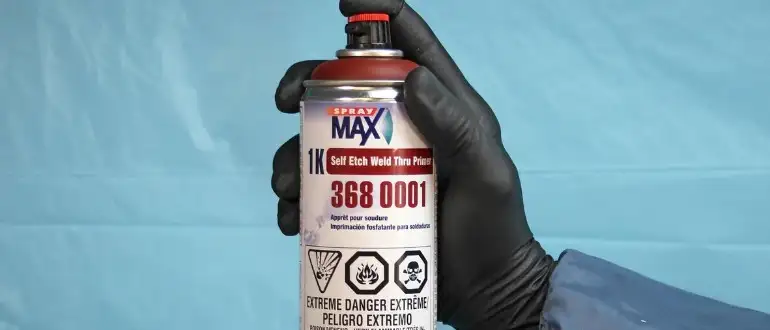

A self-etching primer is a primer that penetrates metal surfaces and helps to create a good bond between surfaces.

Also, self-etching primers are used on blank metal surfaces or surfaces transferred to blank metal. Now the question is can you weld with self-etching primer?

Table of Contents

Can You Weld Through Self Etching Primer?

Yes, you can weld through self-etching primer. The self-etching primer contains a mild acid that etches the metal surface to promote better adhesion of the paint or topcoat. It also contains a zinc compound that provides corrosion resistance.

Welding through self-etching primer can be done as long as the welder is careful not to overheat the primer. If the primer is overheated, it can release harmful fumes. It would be best if you were welded through self-etching primer using the same welding parameters as you would for the base metal.

The welder should also clean the area around the weld before starting to weld. This will help to prevent the self-etching primer from getting on the weld.

If the welder does get a self-etching primer on the weld, needs to clean it off as soon as possible. If the primer is not cleaned off, it can cause the weld to be weaker.

Besides, if you are welding on galvanized steel, it would be best to use a zinc-specific welding rod to avoid contamination of the weld pool.

Some self-etching primers also contain a rust inhibitor. Suppose you are welding on rusty steel. It would help if you used a rust-inhibiting welding rod to prevent the formation of new rust.

Read More: Can You Weld Carbon Steel To Stainless Steel? Explained!

How to Weld with Self-etching Primer?

The best way to weld with self-etching primer will vary depending on the specific project and materials. Let’s find out some way to weld with self-etching primer.

However, here are some tips on welding with self-etching primer, which include using a clean, dry surface and applying the primer in a thin layer. And allowing the primer to dry completely before beginning the welding process.

When using self-etching primer, starting with a clean, dry surface is essential. Any dirt, grease, or other contaminants on the surface can prevent the primer from adhering or may even cause the primer to etch into the surface, making it more difficult to weld.

Once the surface is clean, apply the primer in a thin layer. If the primer is applied too thickly, it may not etch properly. Allow the primer to dry completely before beginning the welding process.

It is vital to use the proper welding technique to avoid damaging the self-etching primer when welding. If the primer is damaged, it may no longer provide adequate protection and may need to be replaced.

If you are unsure of the best way to weld with self-etching primer. Or if you are having difficulty with the welding process, it is best to consult with a professional.

What are the Advantage and Disadvantages of Self-etching Primer?

There are both advantages and disadvantages to using self-etching primer. One advantage is that it can help create a stronger bond between the paint and the surface.

This can be especially helpful when painting over bare metal or when trying to achieve a smooth, professional-looking finish. Another advantage is that self-etching primer can help to prevent rust and corrosion.

However, there are also some disadvantages to using self-etching primer. One is that it can be more challenging to work with than other types of primer.

It can also be more expensive. Additionally, self-etching primer can sometimes cause problems. If it is not applied, such as creating a rough finish or causing the paint to peel.

Overall, self-etching primer can be a helpful tool for painting projects. But it is crucial to weigh the pros and cons before deciding whether to use it.

Is Self-etching Primer Necessary to Weld?

Self-etching primer is not necessary to weld, but it can be helpful in some situations. It can help prevent welding problems by providing a barrier between the metal and the weld.

It can also help improve the weld’s appearance by providing a smooth surface for the weld to adhere to.

If you weld through self-etching primer, the primer will etch into the metal and provide a good surface for the weld to adhere to. However, the primer will also make the weld area more susceptible to corrosion.

You can weld through self-etching primer using any welding process, including MIG, TIG, and arc welding.

FAQs

Yes, you can weld over self-etching primer. The self-etching primer will provide a good surface for the weld to adhere to.

Welding over self-etching primer is not recommended for high-strength welds. The self-etching primer will reduce the strength of the weld.

There is no definitive answer to this question as it depends on the specific application and materials involved. Some self-etching primers are commonly used for welding, which includes zinc-chromate, zinc-phosphate, and manganese-phosphate.

In general, self-etching primers work by chemically etching the surface of the metal to be welded. Which helps to create a stronger bond between the metal and the filler material. These primers are typically used on metals that are difficult to welds, such as aluminum and stainless steel.

Self-etching primer is a type of primer used to prepare a metal surface for painting. It is applied before painting to help the paint adhere to the surface and prevent rusting.

The self-etching primer contains an acidic compound. That etches the surface of the metal, providing a rougher surface for the paint to adhere to. It also helps prevent corrosion by providing a barrier between the metal and the environment.

Final Thoughts

Self-etching primer is a great way to protect your metal from rust and corrosion. It is also a great way to bond metal to metal, ideal for welding projects.

But a self-etching primer can be challenging to work with and can be messy. If you are not careful, it can also cause damage to your metal. When using self-etching primer, follow the directions and use the proper safety equipment.