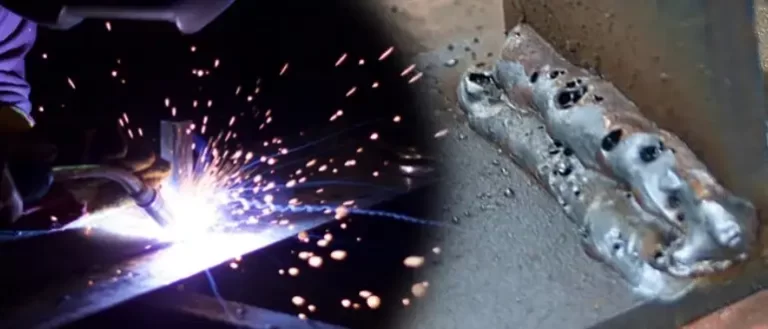

Can You Weld Chromoly To Mild Steel? All You Need To Know!

Can you weld Chromoly to mild steel? If you do, will it create a strong bond or make it a waste of time or money due to the dissimilarity in the metal?

In this guide, you will learn the possibility and the most potent effect. Plus, we share some tips to handle the Chromoly welding process successfully and efficiently.

Table of Contents

Can You Weld Chromoly To Mild Steel?

Yes, you can weld Chromoly to mild steel. However, for the Chromoly welding project, you should use E70S-2 mild steel tig welding rods. E70S-2 will make the bond slightly stronger than mild steel, but not as strong as Chromoly.

Let’s dig in deep!

Knowing about mild steel will help you better understand the possibility of welding it to Chromoly. Mild steel is a kind of carbon steel that contains low carbon.

Considering the definition of Chromoly, mild steel is totally different from it, especially in terms of carbon content. Mild steel contains iron, and it’s not an alloy like Chromoly.

Now the question is, can you weld Chromoly to mild steel? Yes, you can. But make sure you are following the MIG weld process. Despite this, there are a few catches too.

First of all, mild steel won’t do the same job that chromyl will do. Another concern is that due to the differences between these two metals, the joint can crack a little. However, it causes little, so don’t worry.

The last one is that a Chromoly rod is preferable for this project to get better welding results.

Read More: Mild Steel Vs Carbon Steel, Which Is Better?

Pick the Right Filler Materials

When it comes to welding chromyl, you have three choices from which you can pick filler materials. These are ER70S-2, ER80S-D2, and 4130 versions.

ER70S-2 and ER80S-D2 are commonly used in Chromoly welding projects. Specifically, ER80S-D2 contains tensile strength up to 80,000 and it is almost the same as Chromoly. Hence, ER80S-D2 is the perfect choice to use as filler material to weld Chromoly to mild steel.

Conversely, ER70S-2 has a considerably lower tensile strength of 70,000, but it can still deliver enough flexibility. Finally, 4130 Chromoly is also a good option for welding Chromoly as it matches the material that needs to be joined. But it isn’t preferable for thin wall tubes.

A few tips for the Chromoly welding process

The welding method of Chromoly is quite different than that of other metals. You must go after a few tips to make the welding tough, durable, and smooth.

- If you need to weld Chromoly that is thicker than 0.12 inches, then you should preheat the metal. For joining thicker tubing with Chromoly tubing, preheat the Chromoly at a temperature of 300 to 400 degrees F.

- If using a TIG welder, weld more slowly than usual.

- For welding, a Chromoly lift arc is a better option than a scratch start. The second one is relatively more unstable.

- Slope in and out of the Chromoly slowly, as it’s a fairly temperamental metal and this practice will quickly make it brittle.

- Keep the tungsten near the metal to ensure the cone is narrower.

- Don’t cool down the weld rapidly as it can increase the chance of crackdown.

Read More: Harbor Freight 90 Amp Welder Dc Conversion – Welding Tips & Tricks

FAQs

Of course, you can weld Chromoly with mild steel wire, as well as mild-to-mild welding. Even it doesn’t need to follow any special steps.

Chromoly is a tough alloy. Even using thinner Chromoly gauge tubing, you can get a lighter yet much stronger structure. The thickness of the metal makes all the difference.

Final words

In short, you can weld Chromoly to mild steel. But it requires proper tools and techniques, and TIG welding is better than MIG. If you need to weld thicker Chromoly than.125″, then preheat is preferable.

Unfortunately, you can expect the same result from mild steel as the Chromoly will do. Finally, the downside of this welding project is that it can cause weld cracking due to the difference between these two metals.

Read More: Most Common 3 Hobart Ironman 230 Problems And Solutions